Photonic Technologies in Space Applications: Selection and Acceptance Test Criteria

L.Peñate-Quesada , J. Barbero Gonzalez, E. Cordero Garrido & Demetrio Lopez Molina.

Alter Technology Group, Madrid Spain,

ABSTRACT Photonic technologies have changed the world of communications in the form of fibre optics, integrated optics, electro-optical components and micro-photonics. They offer some compelling advantages compared with their traditional RF counterparts when considered for use in space applications. Therefore, research and development of photonics technologies for space applications in areas of communications, sensing and signal processing has been a major theme for several years.

The use of photonic technologies for space applications has risen the problem related to the ability of optoelectronic and optic components to withstand space environment as all optoelectronic and optic components come from terrestrial applications. Therefore, the development of photonic technologies for space applications has made the selection and acceptance test criteria of all optoelectronic and optic components that are part of the photonic system imperative.

The paper presents a summary of the experience of Alter Technology Group on the mechanical, thermal, radiation and endurance testing on several photonics technologies. In addition the paper describes an assessment related to the reliability of these parts to be used in space applications together with the critical requirements to be considered for associated environmental testing.

Introduction

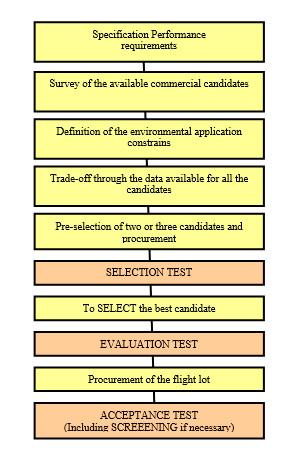

The selection and evaluation procedures of COTS optoelectronic components for its use in space application need to be established due to the fact that no qualified components exists and that no standards are available that define the procedures to be applied for optoelectronic devices to be used in space qualifications. The following paragraphs propose a generic procedure for the selection and acceptance test criteria for optoelectronic devices, and also includes analysis related to the Specification Performance Requirements and Environment Constraints related to space applications.

Summary results of a large number of parts which has been tested by Alter Technology are also presented to demonstrate current status of most promising technologies. Finally, one case example is presented related to optical amplifiers.

Selection and Acceptance Test Criteria

Schematic flow for optoelectronic parts selection

- When COTS components have to be used in space applications because qualified components are not available, then the selection of the right component has to be made in such a way that risk mitigation techniques are applied at the time that the technical requirements of the application are met.

Specification Performance Requirements

Electro-optical requirements

The first step in the parts selection process is the exact definition of the electro-optical performance required for the application. This implies the clear identification of:

- Key parameters.

- Acceptable limits to the range of variation of these parameters during the mission, taken into account:

- Operating temperature range.

- Environmental conditions (radiation).

- Expected mission lifetime.

The key parameters have to be selected in such a way that they allow a wide margin of potential commercial candidates at the time that the performance of the mission is not jeopardized. Some aspects will require the maximum possible flexibility. To make that flexibility possible it is necessary that the selection process is initiated at the first steps of the design, to reduce as much as possible the design related constrictions.

Quality requirements

Quality requirements are determined by the type of mission and application; nevertheless, it is strongly recommended to apply the quality requirements established in ECSS-Q-60A. These quality requirements have to be followed to the maximum extent as possible in terms of:

- Procurement policy

- Screening

- Package and assembly quality and testing.

- Acceptance test criteria

Reliability requirements.

Reliability is one of the main concerns when using commercial components in space applications. This asseveration does not mean that the commercial components are not reliable enough for their application in space, but its real reliability has to be verified. This verification can be performed by means either of the analysis of the reliability data provided by the manufacturer (if available) or by testing, in order to warranty a minimum of 10 years (typical value) of operation in space environment.

Alter Technology Experience on Optoelectronics Parts

Alter Technology Group is a company with more than 20 years of experience in testing of EEE parts for space. In addition to that experience, in the last years, ATGSP is putting an important effort in the development of new capabilities to validate new technologies (i.e. optoelectronics and MEMS) for space applications and to extend these testing capabilities from the part level to instrument or system level.

Based on above, Alter Technology group provides a large experience on optoelectronics parts testing with specific capabilities on optoelectronics measurements as well as mechanical, thermal, radiation and constructional analysis tests.

In addition, the experience of ATSP in the management of space projects together with the commitment of the company with the research and development activities is been reflected in the participation of the company in a large number of projects as coordinator of other research and/or development groups.

A case study can be read at the full report below.

Conclusions and Recommendations

Very few optical components are qualified for space applications. This means that COTS are necessary most of the times. A cost effective approach for selection and acceptance criteria of these COTS has been presented in this paper.

– Detailed construction analysis, endurance, radiation and environmental test performed before the complete qualification flow can be very useful for increasing the reliability of the devices and reducing both the price of the selection and project qualification. It is recommended to do this prior to any project qualification activity.

– Specific test setup conditions must be considered when working with photonics parts to ensure test bench is suitable to provide electro-optical characteristics while parts are being submitted to environmental test in operating conditions.

– Alter Technology Group has a large experience on EEE parts procurement as well as extensive testing on most significant photonics technologies for space applications. Reliability data are available for main parts to help on the final selection of the product for the intented application.

- Electronic components for motor vehicles: the solution in New Space? - 13th September 2019

- Assembly, Integration & Testing in Small Satellites - 2nd August 2019

- Design in Small Satellites - 2nd August 2019