Bulk Optical Materials Typical Test Setup

Talk summary:

The talk about Radiation test on optical materials, will give a general introduction on testing optical materials for use in radiation environments.

A special emphasis is given to thin optical coatings, optical fibers, and fiber Bragg gratings. Here the test procedures are much more challenging than for bulk materials.

The challenges are, amongst others, conflicting standards, often online tests and the necessity to use several different radiation sources.

The talk will give an overview of test standards, especially concerning optical fibers, and a discussion of the influence of parameters such as dose rate, temperature etc.

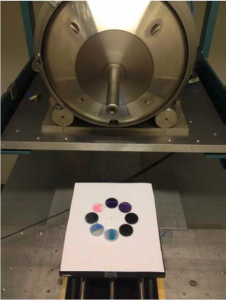

Bulk Optical Materials Typical Test Setup

Radiation test on optical materials

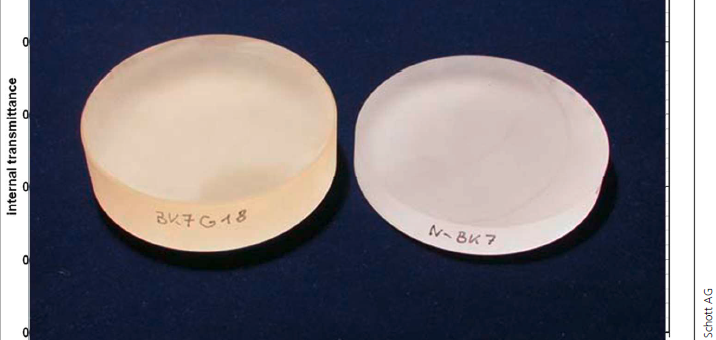

Bulk Optical Materials

- Testing usually done step-stress e.g. optical measurements are done outside the irradiation chamber.

- Testing of induced absorption sometimes done by irradiation lab. For more specialized measurements:

- Bring your own setup. (might not be feasible)

Bulk Optical Materials Typical Results

- Have the samples sent to optical lab (might need more samples, problem with annealing)

- No irradiation standard for optics, but ISO 15856 covers materials in general:

- Use protons with 2 MeV to 200 MeV and electrons > 0.5 MeV (electrons can be substituted by Co-60 which has no ESD problem)

- Some materials (e.g. transparent polymers) are very sensitive to oxygen. Irradiate in vacuum (max 10-2 Pa) or inert gas

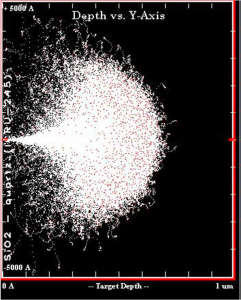

Irradiation planning for protons (50 keV protons)

Surface Effects

- ISO 15856 classifies surface effect up to 4 mg/cm² (about 18 μm SiO2)

- Surface effects are a problem in environments with high fluxes of low energy particles (e.g. radiation belts)

- Proposed particles protons with energies of 10 keV to 1 MeV and electrons from 10 keV to 500 keV, no Co-60!

- Problem for thin optical films, especially when directly exposed to space

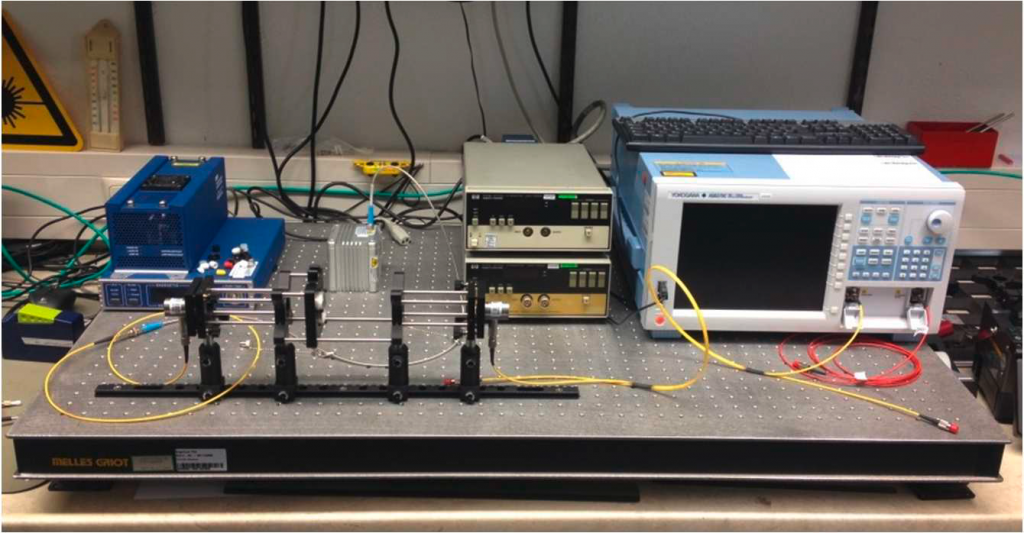

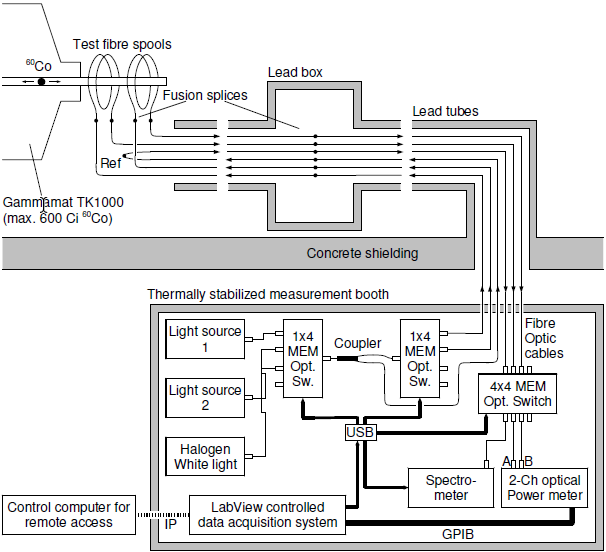

Optical Fibers

Testing is usually done online

Typical Irradiation Setup

Fiber Bragg Gratings (FBG)

Test Challenges

- Irradiations are done online, as with fibers

- There might be statistical variations from grating to grating due to fluctuations in manufacturing

- Possibility to test large number of FBGs due to multiplexing

- FBGs are strain sensors strain free setup necessary during irradiation

- FBGs are temperature sensors irradiate in environment as temperature stable as possible, correct for remaining variations

Download or read the full report here

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019