Radiographic Inspection 3D X-Ray – 2D

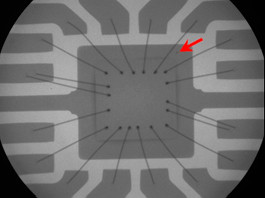

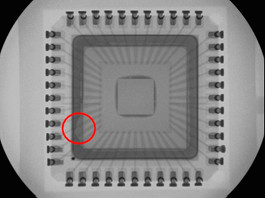

The purpose of the radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as the presence of foreign objects, improper interconnecting wires, inhomogeneities in materials, improper positioning of elements, voids in the die attach material or encapsulating, etc.

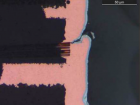

Device flaws detected by X-Ray radiographic inspection.

The sample to be inspected is placed between the source of radiation and the detecting device which collects the radiation not absorbed by the sample. The amount of radiation reaching each area depends on the density and thickness of the materials, therefore the obtained image is of varying density.

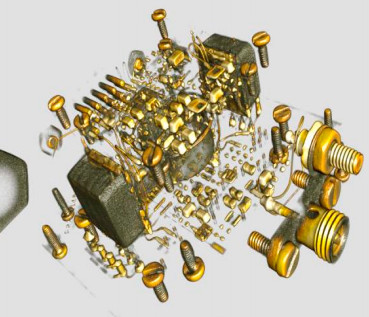

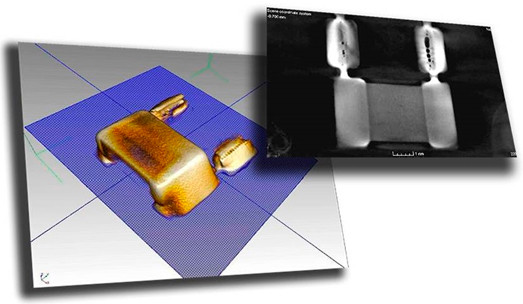

Alter Technology radiation equipment allows using a dynamic radiographic inspection technique, with a possibility to manipulate the sample to display different live views on a monitor, both in 2D and 3D. Additionally, virtual cross-sectioning can be performed allowing to view the 3D internal structure.

3D X-Ray inspection

Radiographic inspection is essentially non-destructive testing that can be performed on most components; however, radiation may cause changes in electrical behavior of some materials. This probability must be taken into account when submitting sensitive devices to radiographic inspection and a safe operation process should be ensured.

- SOLAR CELLS - 30th July 2018

- Radiographic Inspection 3D X Ray – 2D | Hi Rel Electronics Parts - 20th January 2016

- Substrate Attach Strength – Die Shear Strength | EEE Parts - 9th December 2015