ALTER test laboratories devoted to Small Satellites have received the statement for compliance

The statement of compliance is acording the requirements of ECSS-Q-ST-20-07C as tailored from ESA-TECQQ-TN-024614 issued by the European Space Agency (ESA) ECSS-Q-ST-20-07 standard sets the quality and safety requirements for space test centres.

ALTER has adapted its test facilities to the demands of New Space to provide the test activities required to put a small satellite into orbit: thermal vacuum test facility, clean area, vibration, shock test facility, and electromagnetic compatibility laboratory.

Small sats testing improves time to market at a lower cost, contributing to the manufacturing process’s profitability and ensuring the spacecraft’s reliability, securing the mission’s success.

With the commercialization of the space sector, known as NewSpace, and thanks to the expansion of new products called small Satellites, Alter Technology, once again at the forefront of new technologies, offers a comprehensive one-stop service covering all quality assurance tests applicable to small Satellites:

- Proper component selection

- Performance, environmental & reliability tests

- Custom solutions for miniaturization and de-risking

- Full in house capabilities for small satellites validation

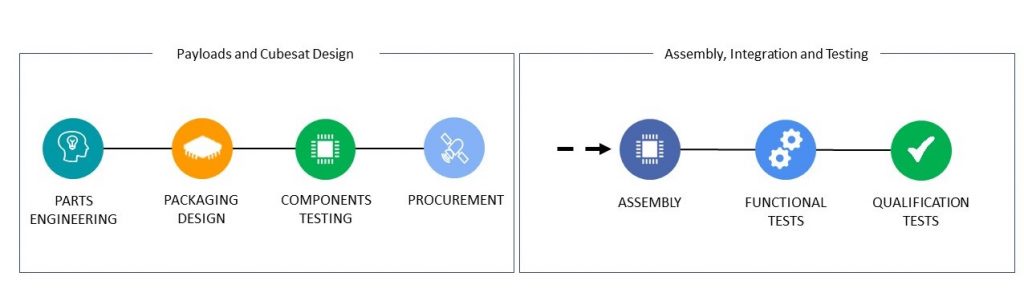

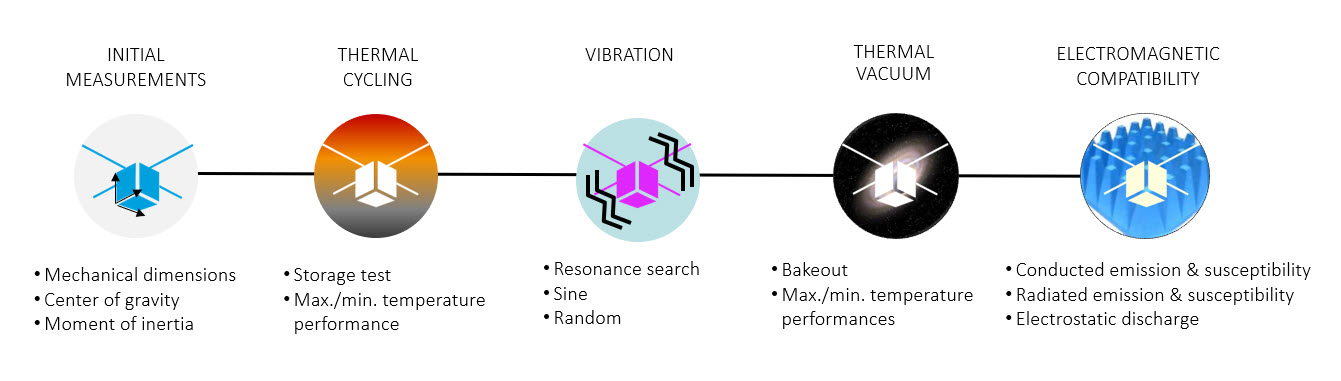

To create an ADDED VALUE IN small Satellites, we have two defined phases that require a series of specific tests.

Design

- Part Selection

- Parts Procurement

- COTS assesment

- Reliability and Feasibility, Risk Mitigation

- Custom Designs

- Packaging

Assembly , Integration & Testing

- Handling and storage

- Test bench design

- Functional and realiability testing

- Qualification & Acceptance Flow

PARTS ENGINEERING

PARTS ENGINEERING

We offer the only tool of HI-REL Parts for Space, doEEEt.com, where the selection of components and all their information is located on the same platform.

What can we find in doEEEt?

Parts selection based on:

Parts selection based on:

Parts approach requiring technical analysis

- Radiation levels, dominant effects, ….

- Working temperature conditions: ranges and cycles

- Demanded technologies to achieve mission challenges,

- Identification of equipment – component criticality within the satellite

- Mission acceptance risk at different levels

- Component volumes, constellation size, recurrence,

- Time frame

- Cost

- Traceability

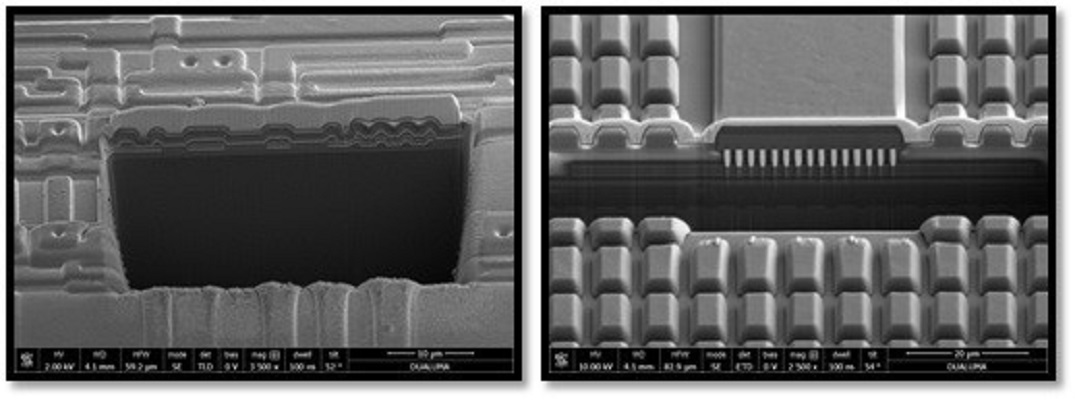

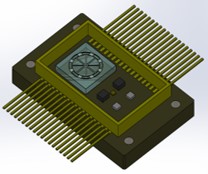

PACKAGING DESIGN

As a group, Alter Technology makes available to our customers a specialized packaging engineering in co-work in Optocap.

Optocap provides contact package design and precision assembly services for a wide range of optoelectronic, microelectronic and MEMS devices. We offer end to end backend semiconductor manufacturing from wafer singulation to assembled product.

COMPONENTS TESTING

- Destructive physical analysis (DPA) & Constructional analysis

- Electrical, RF & Optical measurements

- Particle impact noise detection (PIND)

- Optical microscopy, high magnification

- Scanning acoustic microscopy (SAM)

- X-ray inspection (static and dynamic)

- Scanning electron microscopy (SEM)

- Microanalysis of disperse X-ray energy (EDAX)

- Seal test

Environmental Tests

- Mechanical testing

- Humidity testing

- Thermal cycling, Thermal Vacuum and Thermal shock

- EMC testing on integrated circuits

Reliability

PROCUREMENT

- Risk analysis and management

- Suppliers selection

- Manufacturer liaison

- Cost and schedule estimation

- Parts procurement and purchasing

- Dice procurement

- Export license management

- Sources inspections (PreCAP, CSI),

- Follow-up

- Recovery planning

- Easy access to information thought an interactive web system

FUNCTIONAL TESTS

Combined strain and extreme temperature

Combined radiation and cold temperature

- Test as fly approach

- Test bench development

- Combined environmental & reliability tests

- On line monitoring.

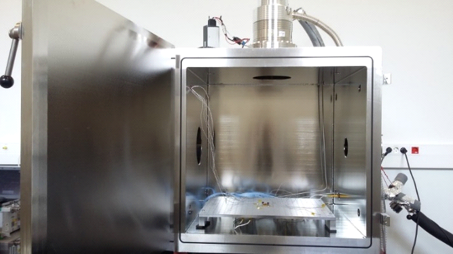

Thermal Vacuum & Bake-Out Tests

- Temperature range: -150ºC to +200ºC

- Vacuum: <10e-6mbar

- Internal volume: 70cm3 with hot plate of 50cm2

- Wide variety of electrical, optical, RF, High power, linear and rotary motion vacuum feed-throughs

- Quartz Crystal Microbalances for molecular contamination and outgassing measurements during bake-out tests

Thermal & Humidity Tests

- Temperature range: -183ºC to +400ºC

- Temperature rate: up to 48ºC/min

- Electrical, thermal, RF and optical feed troughs

- Internal volume: up to > 1000 l.

- 10 chambers, different internal dimensions.

Burn-In, Lifet Test and Hunidity Chambers

- Heating up to +350ºC

- Humidity and temperature control

- Several chambers

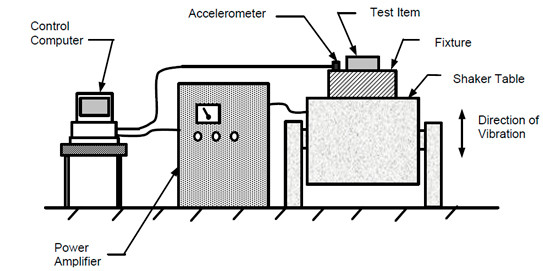

ELECTRODINAMIC SHAKER

- Shaker with slip table and expender head

- Frequency: dc-3kHz

- Force: 35.6 kN

- Displacement: 76mm

- Acceleration:110g (sine pk), 75g (random RMS)

- Sliding table working área: 900 x 900 mm

- Vertical Laminar Flow Chamber (Optional)

- Cleanliness: Laminar Flow Chamber ISO 5

Mechanical Shock

ATN Shock Response Spectrum Analyze System

- Drop method to simulate pyrotechnic shocks

- Frequency: 100Hz to 10kHz

- Shock levels up to 3000g; Q=10

- SRS Analysis software computes the Shock Response Spectra up to 1/12 octave

- Triaxial and monoaxial shock accelerometers

- 8 channels

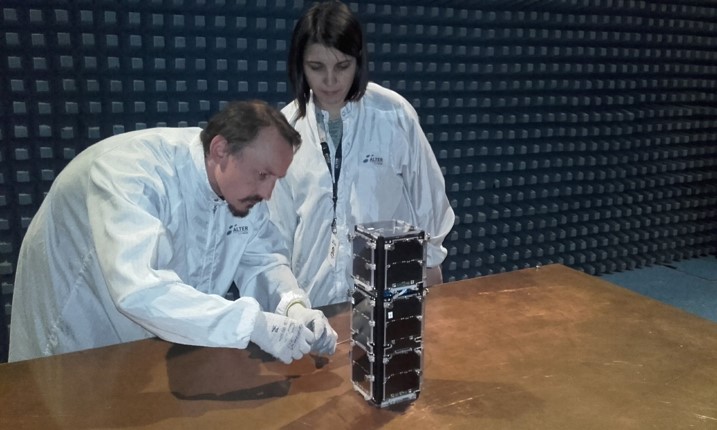

EMC Testing

Main competence areas:

- Radio & telecom (CE), traffic (CE) and railway,

- Air traffic management (CE), medical (CE), space flight equipment

- Military, space & aeronautical chamber

Main facilities:

- Two semianechoic chambers

- 11m x 8.5m x 6m hybrid absorber

- 7.5 m x 4.5m x 4m

- GTEM

NOTIFIED BODY & ACCREDITED LABORATORY

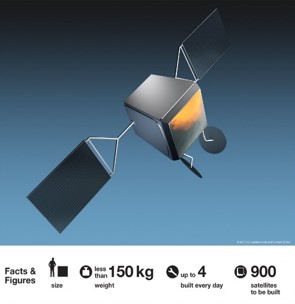

Key Factors on Small Satellites Development

Mass and Volumen

- Miniaturization

- Use of MEMS

- New packaging concepts

- State of the art technologies

Safety and reliability

- Reliability analysis

- Space debris

- Risk analysis

Normative and Regulations

- Collection of ESCC specifications and procedures

- Related ISO normatives

- NASA Cubesat 101 approach

- Custom…

Budget and planning

- Use of COTS

- Test as you fly