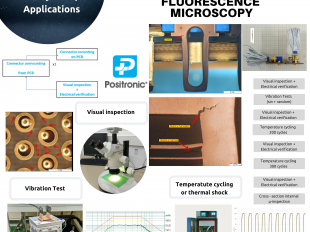

High reliability assembled PCB prototypes as well as novel surface mounted devices (SMD) and mixed systems must be assessed according to well defined qualification test plans. Such high reliability verification programmes are not limited to just evaluate the robustness...

The burgeoning demand for the incorporation of disruptive technologies into space industry clearly requires fast and reliable procedures for the space qualification of these innovative components. This also entails a close collaboration between the manufacturing and...