Humidity may affect the life expectancy of a component by creating stresses on the part materials and altering its electrical properties in a way that the component reliability is significantly diminished.

Temperature Humidity Test is those performed with the aim of evaluating the properties of materials used in components and the reliability of non-hermetic packaged devices in humid environments.

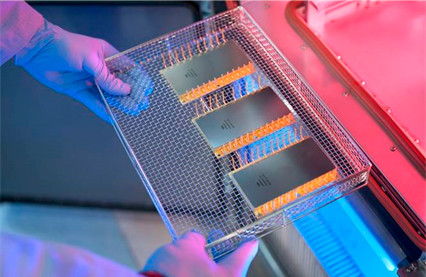

Temperature & Humidity with Bias Test (THB) employs moisture, temperature, and the devices are normally under bias condition, as accelerating factors. The scope is to activate the humidity penetration through the external materials (encapsulant or seal) or along with the interfaces between the external protective material and the metallic conductors and produce degradations and failures. One of the typical test conditions is known as 85/85, meaning 85°C and 85% of relative humidity, and the duration of the test may vary depending on the used test method.

Once the test is completed electrical measurements are carried out. A device will be considered to have failed the THB test if the parametric limits defined in the acquisition specification are exceeded or if functionality cannot be demonstrated under nominal conditions. Additionally, any appearance of corrosion on the parts under test as well as the appearance of visual defects can be considered sufficient for rejecting the parts.

In accordance with the widely used in space and industry JEDEC Standard No. 22-A101C, the duration of the test is 1000 hours.

Under certain conditions and in accordance with the ECSS-Q-ST-60-13C standard on the use of commercial EEE parts in space applications, this test may be replaced by the Highly Accelerated Stress Test (HAST) with the test duration reduced to 96 hours. See HAST page for further information.

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019