Tin Whisker Growth Results comes after the investigations and thanks to the methods carried out by Alter Technology, we can reach some conclusions.

An important starting point must be stressed that NONE OF THE “AS RECEIVED” SMD DEVICES POSSESSED WHISKERS. It was confirmed by performing a visual inspection. This was repeated by the company, with the help of the SEM, on the three lots of devices after each of the four runs for conditions of Temperature Cycling, and the Ambient- and High-Temperature/Humidity Storage.

In contrast:

According to the JEDEC standard, any tin whisker having a length of more than 40μm is potentially harmful and must be identified and recorded.

Alter Technology has measured the length of the whiskers using the radial method, i.e., considering that the length is defined by the most distant point of the whisker to the point of the surface where originates.

How are the results?

Alter Technology detected and measured the first two whiskers with a length more than 40μm (100μm and 150μm, respectively) in one BDS4.6/3/8.9-4S2-Z part after two runs of 1000 hours or approximately 12 weeks. This means a LOW whisker density range according to JESD22-A121, Para. 6.7, Table 5.

Other samples of the same lot showed whiskers too, but with lengths less than 40μm.

| wdt_ID | Maximum Whisker Density Range | Total Number of Whiskers per Lead or Termination | Lead or Termination Inspection Area |

|---|---|---|---|

| 1 | Low | < 10 whiskers | (mm2) |

| 2 | Medium | 10-45 whiskers | (mm2) |

| 3 | High | > 45 whiskers | (mm2) |

| Maximum Whisker Density Range | Total Number of Whiskers per Lead or Termination | Lead or Termination Inspection Area |

Table 4. Whisker density ranges that can be determined based on the number of whiskers observed per lead or termination.

After three runs, and in addition to those observed during the previous step, whiskers with more than 40μm (between 51.8μm and 100.3μm) were detected in five new BDS4.6/3/8.9-4S2-Z parts. Obviously, the number of whiskers with a length more than 40μm increased but the density was still LOW. Some of the BDS3-3-8.9-4S2-Z and BDS3/3/8.9-3S1-Z parts showed whiskers too but with lengths less than 33μm and 28μm, respectively.

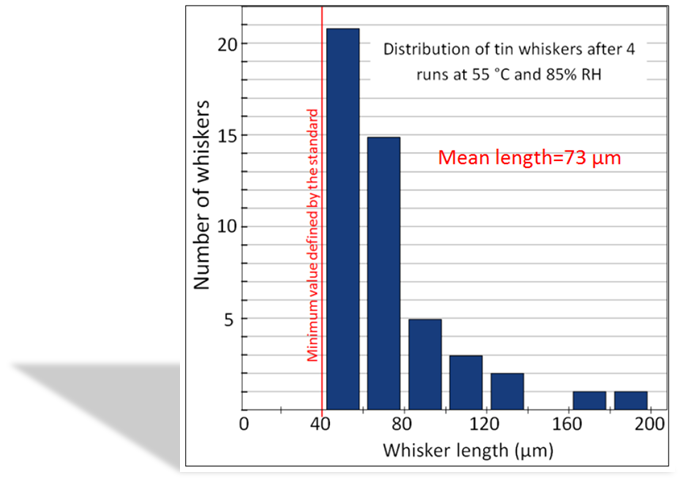

Finally, and after the fourth run (accumulated duration time of 4000 hours, or approximately 24 weeks) of High Temperature/Humidity Storage test conditions, the number of whiskers found was much higher, with lengths above 40μm on 24 of the beads. However, the density thereof was still considered LOW in according with JEDEC standard.

Summarizing, and after the completion of High Temperature/Humidity Storage tests, the most relevant results were:

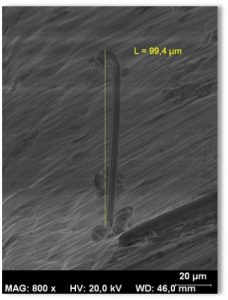

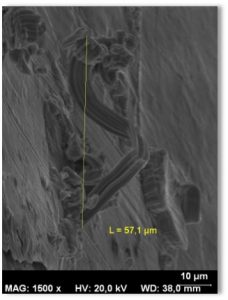

Three parts showed one whisker with lengths of 99.4μm, 57.1μm and 118.9μm, respectively.

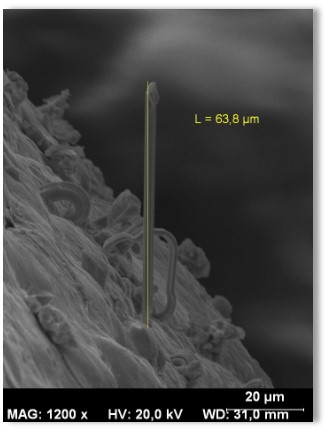

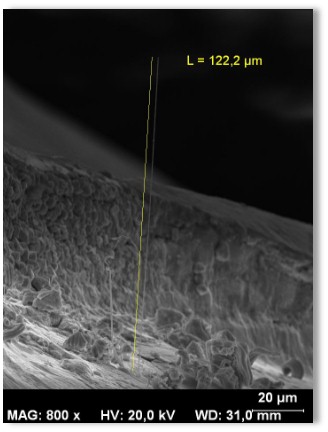

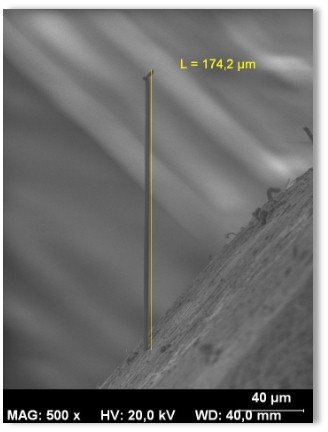

Figure 12. SEM images representative of the Sn whiskers found when the samples were stored for more than 4000 hours (24 weeks approximately) at 55ºC and 80% RH

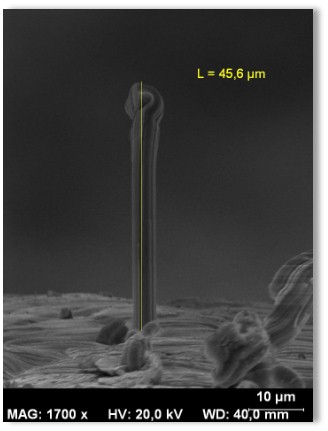

This lot had six parts with one whisker each with lengths between 44.6μm and 90.7μm. And also two parts with two whiskers (one per contact) with lengths between 46.8μm and 122.2μm.

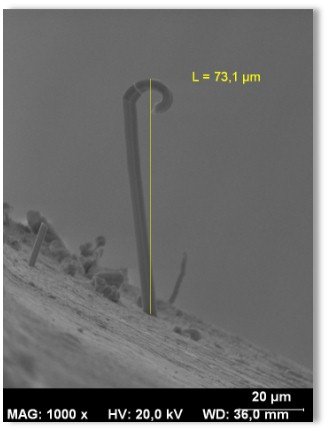

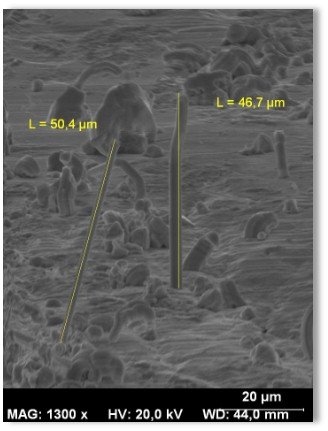

Figure 13. SEM images representative of the Sn whiskers found when the samples were stored for more than 4000 hours (24 weeks approximately) at 55ºC and 80% RH.

In the last lot, whiskers were found in the 13 devices and in most of the contacts. In total, 41 whiskers were counted with lengths ranging from 43 to 192μm. And up to three whiskers were found attached onto several contacts.

Figure 14. SEM images representative of the Sn whiskers found when the samples were stored for more than 4000 hours (24 weeks approximately) at 55ºC and 80% RH.

These results show that the amount of long whiskers in the third lot was very high when compared to the previous two lots even though the three lots of SMD parts had been made with the same manufacturing process and dimensions of the contacts.

Figure 15. Whisker length distribution after 24 weeks of High Temperature/Humidity Storage.

- Tin Whisker Growth Results - 31st July 2018

- Tin Whisker Growth Conclusions - 31st July 2018

- Tin Whisker Growth Experimental Methods - 17th April 2018