Alter Technology Procedure

Counterfeit electronic components are defined as:

- Substitutes or unauthorised copies of a product

- A product in which the performance or the materials used has been changed without notice

- Items that are deliberately altered in such a way as to misrepresent the actual quality of the item with the intent to defraud or deceive the purchaser

- Parts with different characteristics and/or quality

The wider use of lower-cost parts, as well as nonverified procurement channels, are spreading the problem, being also prevalent in the medical and space markets.

Alter Technology being concerned about the issue and aware of its impact on our customers has unilaterally defined a complete process of the technical management of the supply chain, from the supplier selection and monitoring all the way, through to the inspections and testing techniques aimed to prevent counterfeit components entering the manufacturing line. This procedure is based in three pillars:

- ESA, SAE and UNE standards (Alter Technology is ISO 9001 and ISO 9100 certified)

- Long experience in the field of electronic components procurement

- Full in-house capabilities (Alter Technologylaboratory is ISO 17025 accredited)

Alter Technology quality system is in line with guidelines of SAE international per AS6081 (Fraudulent/Counterfeit Electronic Parts: Avoidance, Detection, Mitigation, and Disposition – Distributors):

- Customer Related Contract Review, Agreement, & Execution

- Purchasing

- Purchase Order Requirements

- Supply Chain Traceability

- Verification of Purchased Product

- Material Control

- Reporting

- Personnel Training and Certification

The counterfeit mitigation internal procedure issued and implemented by Alter Technology describes the requirements for procurement and validation of EEE parts oriented to risk minimization/avoidance of counterfeit parts procurement, including final disposition.

The standard activities included in the procedure to counteract the risk of counterfeit components making their way into the manufacturing process are:

- Supply chain monitoring

- Manufacturer liaising

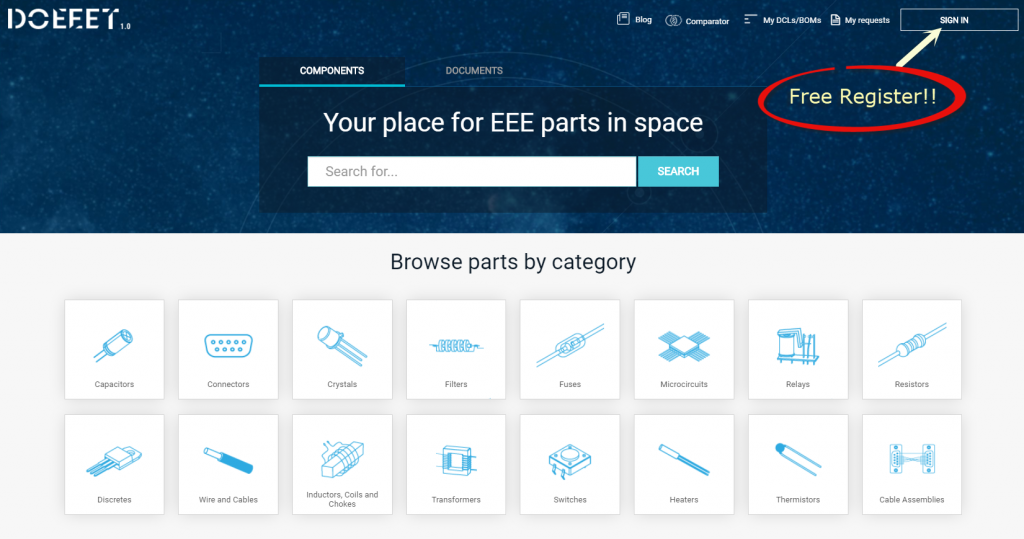

- Development and maintenance of the components reporting and database

- Training in counterfeitprevention

- Using proven sources of procurement

- Single lot procurement if possible

- Safe long-term storage facility for validated parts

- Compliance verification (authenticity analysis) by performing various inspections:

- Comparison with known authentic samples in conjunction with the technical support and assistance from the original manufacturer

- Manufacturer and supplier documentation review. Verifying lot documentation and traceability

- External visual inspection

- Radiographic inspection

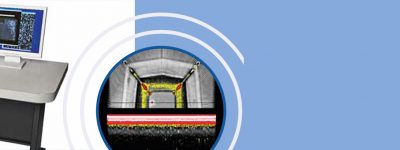

- Scanning Acoustic Microscopy

- Electrical measurements (random)

- Internal visual inspection (random)

Alter Technology is highly committed to mitigate the counterfeit problem, and in order to eliminate the possibility that such components enter in your manufacturing line, and to reduce the risk to the maximum extend, in addition to the activities included in AS6081, Alter Technology includes into its capabilities portfolio, a full set of additional tests and activities which can be used as a complement to get the needed validation and verification of the components:

- Resistance to solvent or marking permanence test

- Lead finish material analysis, by XRF and EDX

- Thermal cycling

- Burn-in

- Hermeticity Verification (Fine and Gross Leak)

- Other inspections as specified.

- Supply chain monitoring

- Manufacturer liaising

- Development and maintenance of the components reporting and database

- Training in counterfeit prevention

- Using proven sources of procurement

- Verifying lot documentation and traceability

- Single lot procurement if possible

- Compliance verification (authenticity analysis) by performing various inspections

- Comparison with known authentic samples in conjunction with the technical support and assistance from the original manufacturer

- Safe long-term storage facility for validated parts

- Authenticity test