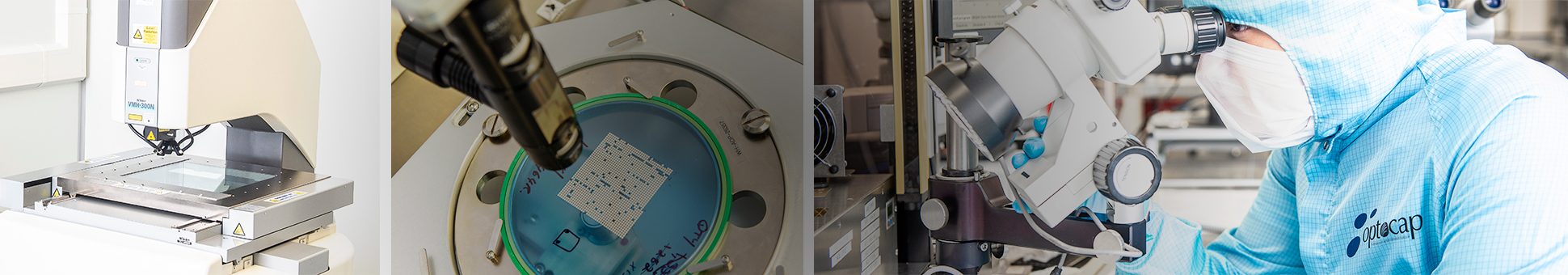

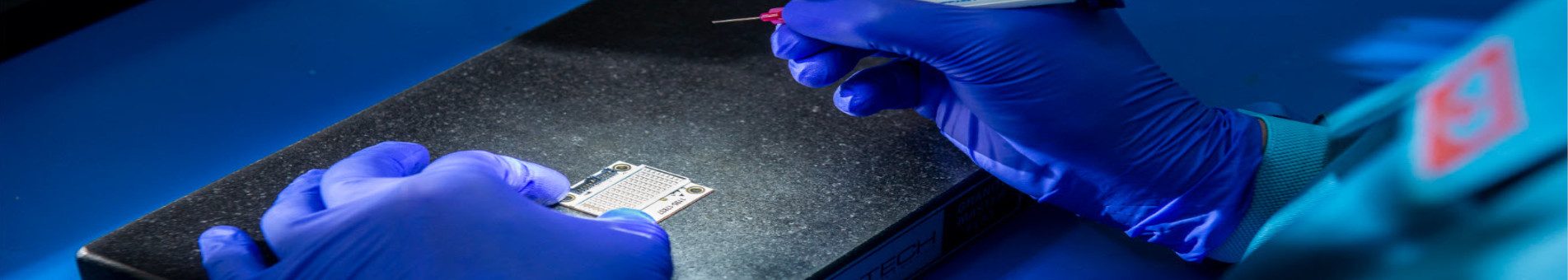

Providing contract package design and assembly service

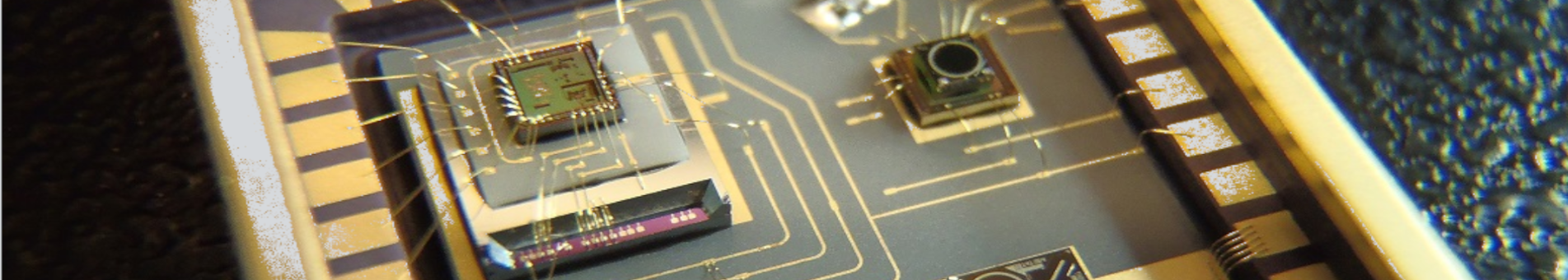

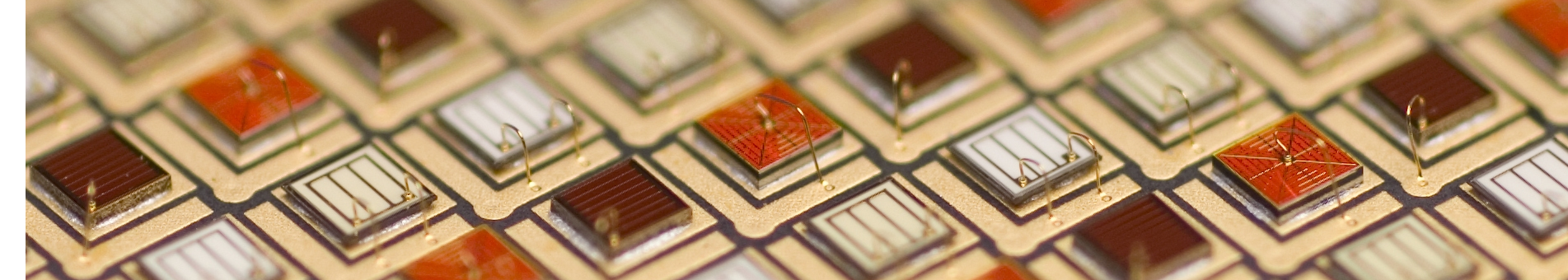

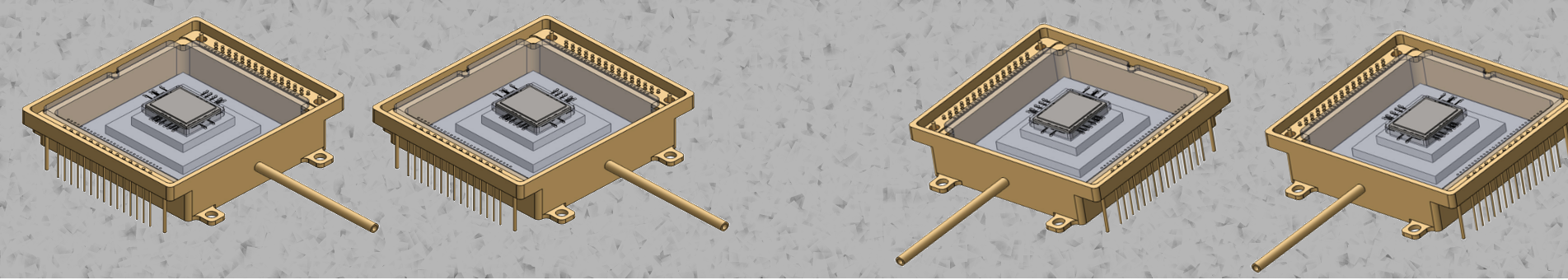

Alter Technology (formerly Optocap), provides contact package design and precision assembly services for a wide range of optoelectronic, microelectronic and MEMS devices. We offer end to end backend semiconductor manufacturing from wafer singulation to assembled product.

SERVICES & PRODUCTS

Alter Technology UK, process and design IP and know-how enable our customers to reduce development and manufacturing costs, accelerate time to market and reduce risk with any new product development.

Our expertise in semiconductor packaging solutions spans the full product life-cycle: from design through prototyping, process optimisation, product qualification, failure analysis, volume manufacturing and transfer to low-cost volume manufacture.