Optocap’s expertise and capability in Encapsulation and Hermetic Sealing will reduce risk and reduce time to market as well as providing a cost-effective manufacturing option.

Tag - encapsulation

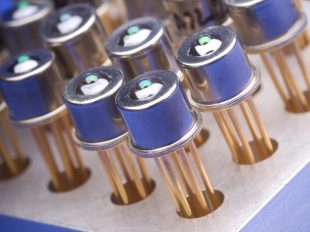

Encapsulation is the process to protect die from damage after die attach and wire bond. There are two main types of encapsulation: Glob Top and Dam and Fill.

Glob top is a process whereby a low viscosity encapsulant is dispensed on top of the die.

The encapsulant flows and conforms to the shape of the die without damaging wire bonds.

However, the encapsulant can flow beyond the desired area and into adjacent areas. In many applications, such as the encapsulation of MEMS devices and Concentrated Photovoltaic devices, a controlled partial encapsulation of certain selected regions, for example wire bonds, is required, but ensuring that the active surface of the device is free from encapsulant. The tight control for partial encapsulation requires selection of a suitable encapsulant and development of an appropriate dispense process.

by Optocap