About Us

During three intensive months the Digital Academy has assigned a cross-functional team consist of people from different parts of an organization to analyse de feasibility of one of the most complex project proposed during Ahaus event, the Virtual Lab.

The team is composed of two innovation managers from Industrial Services as well as two senior engineers from the Aerospace, with the support of most of the technical staff from Alter Technology test laboratories.

The project mainly has focused in the test related to Alter Radiation Laboratory,

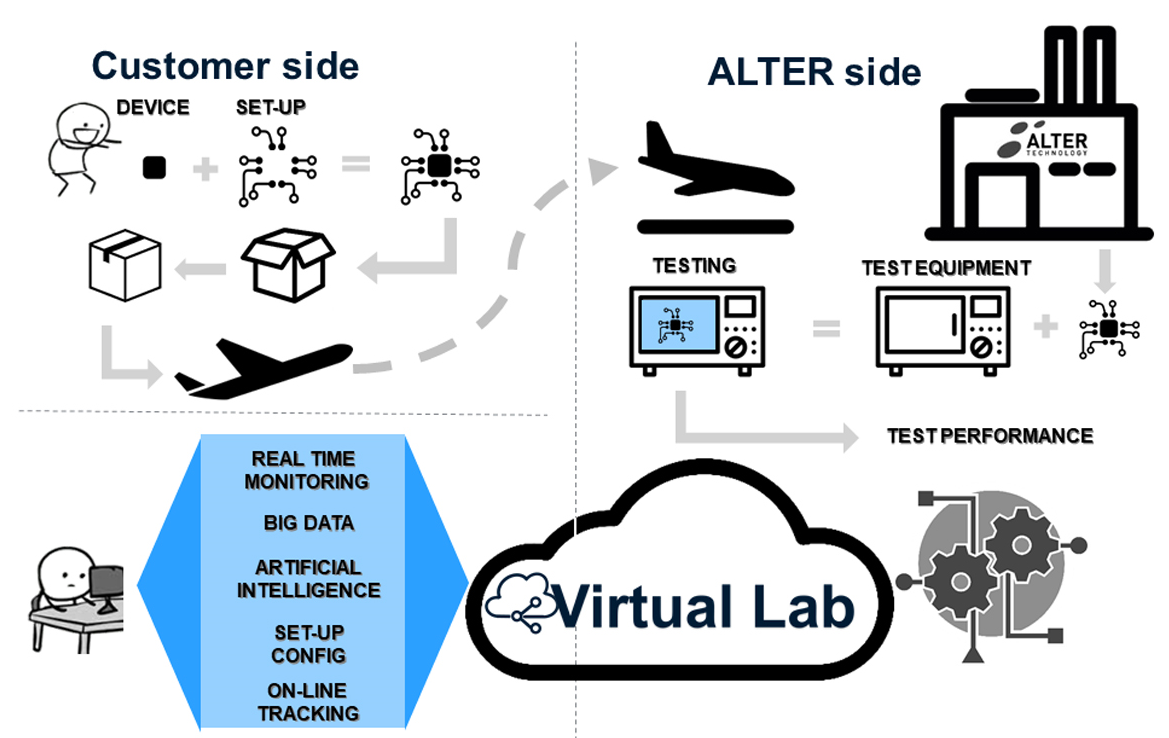

How Its Works

The system is designed as a virtualization of testing laboratory, that means the any customer may access to a certain service through the web without the need to invest on expensive equipments neither the need to be physically present during test execution.

The main characteristics that this new service will provide to the client is:

- On-line monitoring: The platform will make possible to record and monitor in real time the results of the test conditions to be implemented as well as the intermediate results or the running tests.

- On-line tracking: customer to access at any time to the information related to the status of the test

- Big Data Analysis: Simulating a component’s behaviour before actually testing it can greatly improve design efficiency by making faulty designs known as such, and providing insight into the behaviour of electronics circuit designs.

- On-line set-up description: The complete set-up description: instrumentation, software and interface definition will be accessible through the platform.

- Artificial Intelligence: In combining machine learning (inputs and outputs) with analytics (behaviours) to facilitate decision making, you have the power to unlock the patterns in this data and improve testing efficiencies

How Its made

Electronics have become an integral part of our lives, as standalone consumer and communications electronics devices and as components in vehicles, homes or industry. Electronics development and production are impossible without test and measurement equipment. The complexity of electronic-device testing varies widely, ranging from the simplest type—manual testing—to the most complex—large-scale automatic test equipment (ATE). Manual testing typically requires DVMs, oscilloscopes, and other equipment set up in a particular configuration. When the device type to be tested changes, you usually need to change the test hardware. ATE testers, on the other hand, provide tremendous flexibility, allowing many different types of devices to be tested without changes to the test hardware. But, these testers can cost upwards of a million dollars.

To solve this complexity, Virtual Lab covers the most critical needs of testing infrastructures in domains such as:

- Automatic Testing Equipment (ATE)

- Electronic Test and Measurement Equipment

- Data Acquisition

- Computing Platforms

- Data Storage Architectures

- Compute Provisioning and Management

- Networks and Communication

- Data Analytics

Making simple the access to all the results from a single platform. The power of Virtual Lab is not only the instrumentation behind the platform, but the access to predictive analysis. Data analytics (DA) can help understand and gain insights from the big data and in turn help advance towards modelling and simulation for a better decision making.

To learn more about Virtual Lab, Industry 4.0 download our PDF presentation.