Red Plague Corrosion

What is Red Plague Corrosion?

The term red plague was coined to describe the red (Cu2O) and eventually the black (CuO) troublesome corrosion by-products observed in silver-plated copper conductors. Both corrosion products are generated by the electrochemical reaction induced when a galvanic cell is formed between the copper core and the silver-plating. During this process, the sacrificial corrosion of the copper core leads to the loss of the mechanical properties, including strength and ductility. Hence affected wires do not withstand the hard shock and heavy vibrational g-load imposed by space flight. Moreover, excessive corrosion can impair the electrical conductivity and the fatigue life of these conductors in conventional applications.

Who is affected by Red Plague?

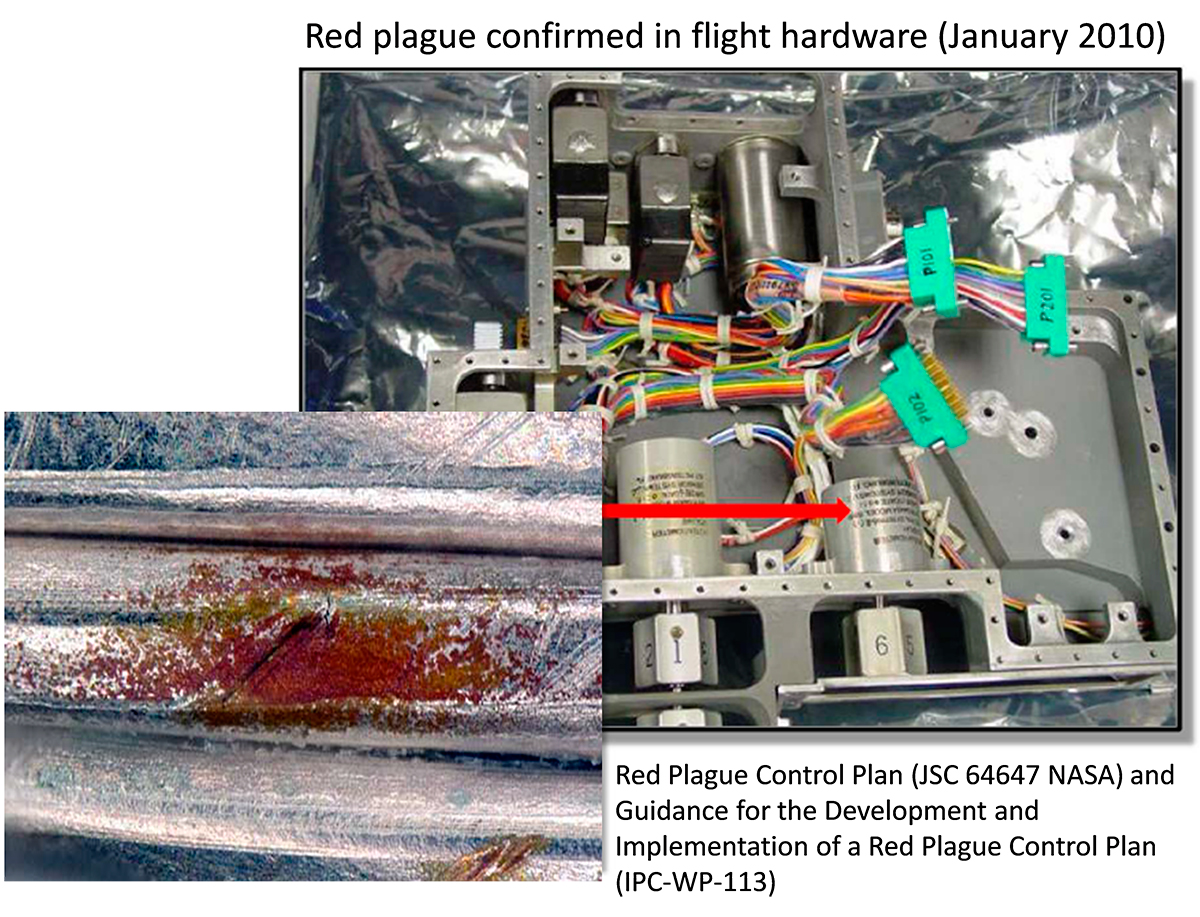

Any industrial application that makes use of silver-plated copper conductors is exposed to red plague and due to its adverse effects this is a critical issue in either military, aerospace or space systems. Thus several documents mentioning and warning about the red-plague risk have been published by different national and international agencies (ECSS, ESA, NASA, Mil Spec of the Defense Logistics Agency, USAF, SAE International, ASTM International, IPC Association, and others not included in the following table). In particular ,the “Determination of the Susceptibility of Silver-Plated Copper Wire and Cable to Red-Plague Corrosion” (ECSS-Q-ST-70-20C) and the “Red plague control plan” (JSC 64647) specifications, issued by ECSS and NASA respectively, state protocols and procedures to prevent the installation in spacecraft systems of red-plague susceptible conductors.

Red Plague References

What causes Red Plague?

Although other undefined agents may also play a role, red plague is initiated if both moisture and oxygen are present at the silver cupper interface according to the following reactions.

Therefore ESA studies concluded that silver plating must be defect free and provide a homogeneous sealing. Hence a minimum plating thickness of 2 μm was stated for spacecraft applications in order to prevent the red-plague development (ECSS specifications). Despite such precautions, manufacturing processes may induce small imperfections in the silver coating (e.g. porosity or deep scrapes penetrating the silver plating) and expose the copper core of a wire strand to environmental agents.

In fact, the primary initiators of red plague are mechanical damages produced during manufacturing: wire-drawing operations, wear in stranding and braiding processes, insulation or wounding of bobbins. Such red-plague precursor seeds may also be the result of mishandling (e.g. excessive force during either installation or maintenance operations).

Similarly, an improper fabrication process whereby moisture becomes trapped during the plating may also induce red plague corrosion.

Once initiated, in the presence of oxygen and moisture the sacrificial corrosion of the copper core continues and spreads indefinitely and compromises the integrity of the conductor. Under suitable conditions, this process can proceed very quickly and produce the total circuit failure before being detected by regular visual inspections.

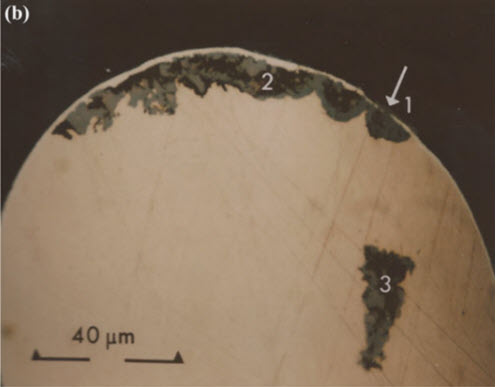

The image shows the red-plague propagation hidden underneath the silver coating of a Cu wire. The micro section (left) also shows how the copped corrosion is initiated by a micrometric defect at the silver plating (arrow 1).

Materials and processes for Spacecraft and High-Reliability Applications, Barrie D. Dunn, Springer International Publishing Switzerland 2016

Red Plague screening test

As indicated before, regardless of the quality of the plating process red-plague precursor seeds can be formed during the manufacturing process. At the first stage, they do not affect the conductivity of the systems and a specific test has to be used to assess the red plague susceptibility of each conductor. According to the specification ECSS-Q-ST-70-20C the red plague screening method conducted at our laboratories is based in the procedure suggested by Anthony and Brown in their pioneer work of 1965.

This is an accelerated test method whereby the analyzed wire is exposed to accurately-controlled oxygen, moisture and temperature conditions. The used set–up, which includes a thermal bath for temperature regulation and an accurate oxygen dosage system, is able to simultaneously treat up to 6 wires, which is an important characteristic considering the long test-duration (10 days). Under the test conditions, the presence of plating imperfections will lead to the fast development of the red-plague “infection”.

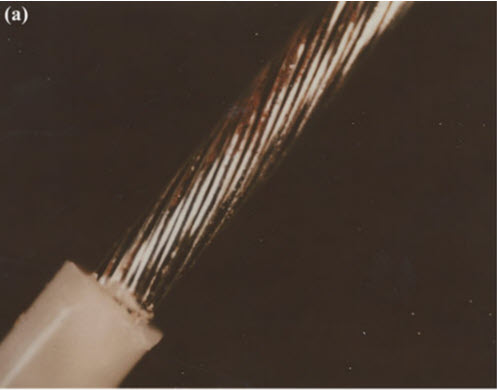

Thereupon exposure the sample is inspected my optical microscopy in the search of corrosion sings and classified according to the acceptation criteria stated by ECSS specifications. The image showss a rejected sample due to the red stains observed after the red plague test (left top).

A microsection carried out in our laboratory in a non-affected wire (left bottom) is also included to illustrate our capability to discard the presence of inner red-plague traces.