Alter Technology is a quality driven company providing procurement, engineering and test services for Space Components, Hi Rel Components, E.E.E. (Electrical, Electronic and Electromechanical) components and electronic systems, within the space and harsh environment markets, where failure is not an option.

We work in many markets including, but not limited to, Aerospace, Security, Transport, Emergency Services, Health & Safety and Automotive.

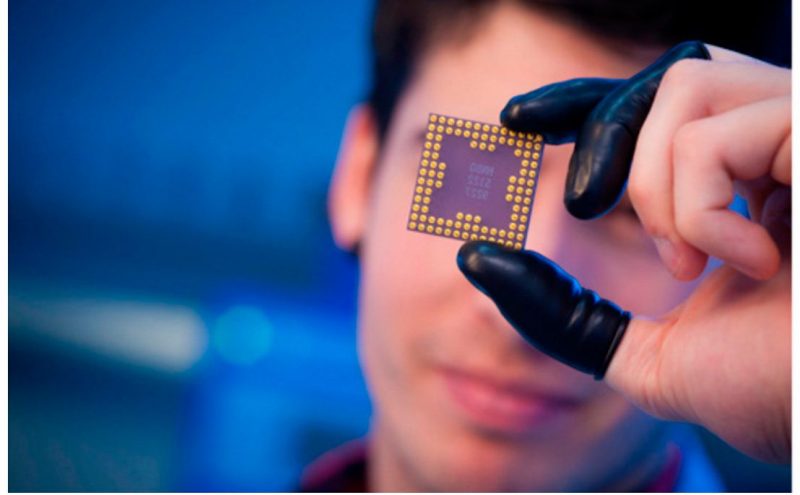

Space Electronics Components

The E.E.E. (Electrical, Electronic and Electromechanical) components are the basic elements of any electronic system which are the fundamental building blocks that determine the final equipment performance, in terms of the electrical performance, mechanical strength, and ability to meet the environmental stresses they will encounter in service.

Highly skilled teams, deliver innovative solutions for counterfeit avoidance, failure analysis, FPGA programming, component screening, radiation, test and optical component evaluation and qualification, to verify the suitability of the selected .

Engineering of Space Components

Ensuring technical compliance with the project requirements;

The procurement of EEE components for space and other harsh environment applications requires a high degree of engineering experience and expertise provided in the form of technical support, to ensure technical compliance to the project requirements. The technical support starts from the initial customer enquiry stage, with the correct component selection-and definition of the component number, procurement requirements, and qualification steps and processes, to the final delivery stage. We ensure that the delivered component is fit for use in terms of functionality, reliability, quality and radiation assurance.

Testing on EEE Components

Hi Rel Components, E.E.E. components are the basic constituents of any electronic system and they are the elements that determine the final equipment performance, including the electrical properties, the mechanical strength, and its ability to perform over the harsh environment conditions of each application. To guarantee this objective, it is often needed to perform a wider range of tests and inspections than the manufacturer performs in order to make a full assessment as to whether a device is suitable or not for the intended application.

Electronic Systems

When launching a product to market it is necessary to ensure that it meets all required national and international standards and will meet the customer’s expectations in terms of performance and reliability. If the product fails to meet these requirements, this will most likely cause a delay to the project and result in a significant cost increase.

To ensure a successful outcome the product needs to be fully defined from the beginning, in terms of the product technical specification performance requirement, to which it is ultimately designed and certified to meet and to be marked i.e. whether it is CE or MIL. marked

Package design and assembly services for microelectronic and optoelectronic devices.

Alter Technology expertise in packaging solutions spans the full product life-cycle: from design through prototyping, process optimisation, product qualification, failure analysis, volume manufacturing and transfer to low-cost volume manufacture. This provides customers adopting an outsourced manufacturing model with a much simplified and efficient supply chain.

Certifications

To demonstrate that the product meets the requirements;

Conformity assessment to demonstrate that a product or a service meets the requirements of the applicable regulations or standards is a key issue in the process of placing it on the market.

Alter Technology Tüv Nord

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019