Photonics Technologies for Space Applications. Main Advantages

- Almost unlimited bandwidth (i.e. 1550nm fiber can go to several THz.).

- Reduced propagation losses at spacecraft level (due to short communication distances).

- Supports any modulation or coding format. Immunity against electromagnetic interferences.

- Optimum mechanical properties (light weight, mechanically flexible, reduced volume, resistant against corrosion of contamination).

Photonics Technologies in Space applications

Telecommunication Satellites Payload

- Digital Communication Links

- Analogue Communication Links

- Optical Switching

- Signal Processing

- Microphotonics

Spacecraft Platform

- Optical Wireless Low rate Links

- Sensors

- Pyrotechnic

Optical Wireless communications

- IR LEDS

- IR Photo-detectors

Opto-pyrotechnics

LIDARS

Formation flight

- High power lasers

- IR detector (1.55 to ∼4 μm)

S/C visual inspection

- Imaging systems

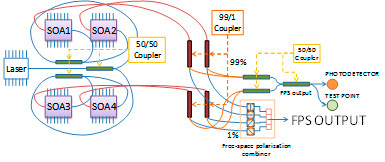

Quantum cryptography

- Laser at different wavelengths

- Micro-optics

- Optical Amplifiers

CASE STUDIES

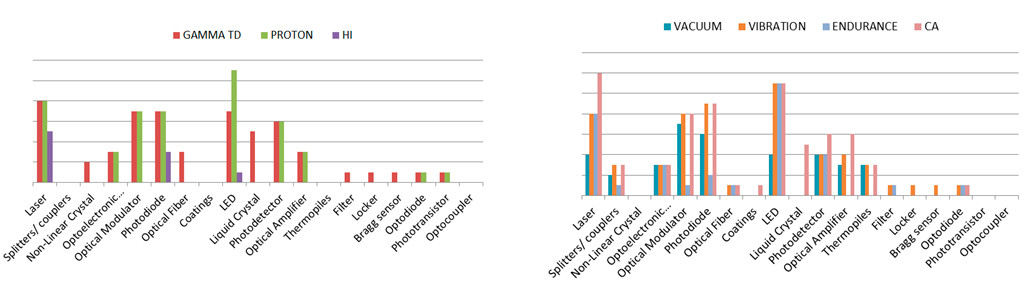

Parts Selection rules for Space Applications

Case Study: SOLAR ORBITER

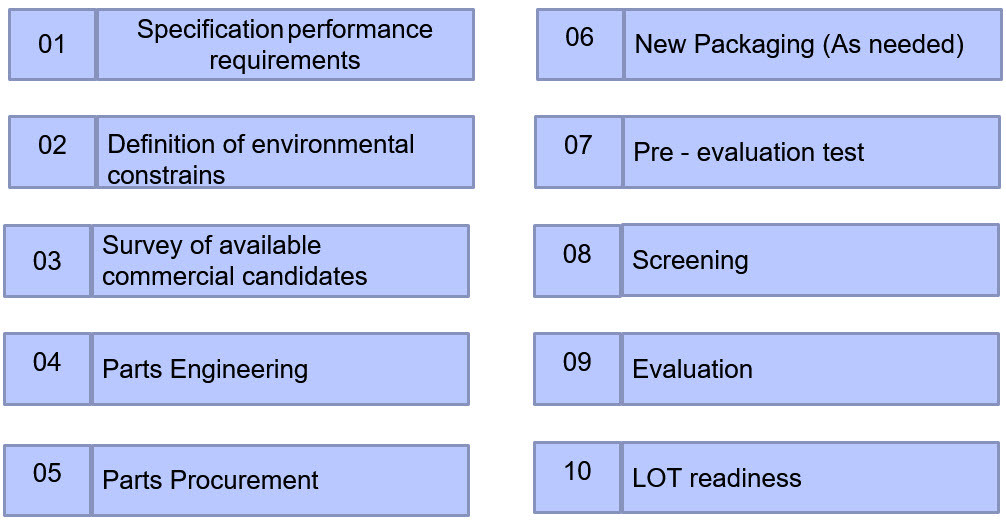

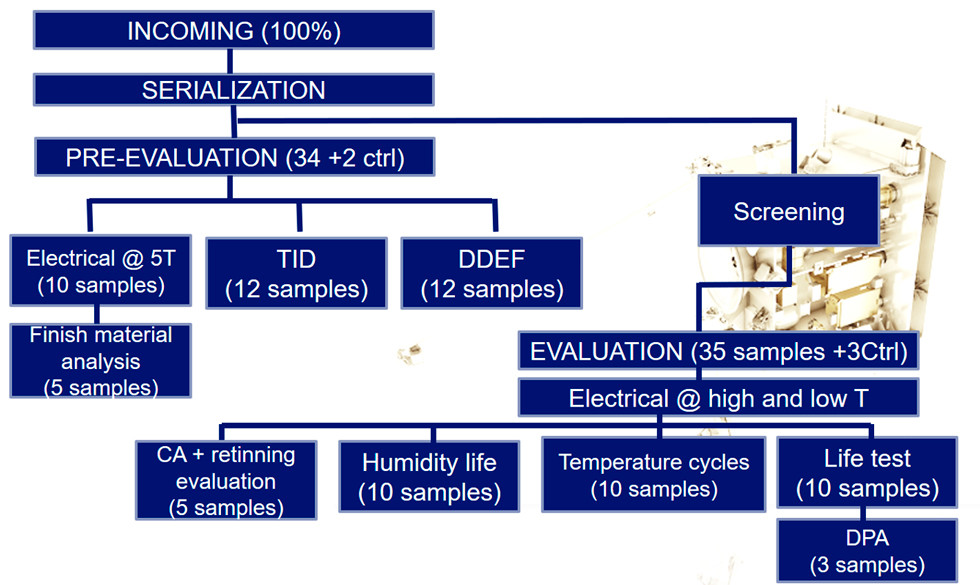

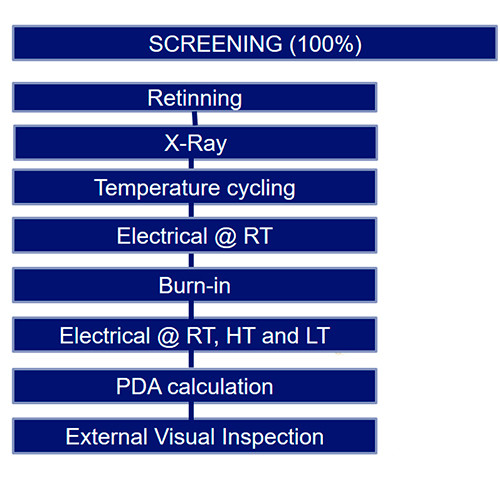

Evaluation & Screening Flow

- Flow based in ECSS-Q-ST-60-13

- PIND and Hermecity were N/A in most of the cases (the components were plastic encapsulated)

- Vibration and shock in evaluation demanded at assembly level (due to exotic packages and assembly techniques)

- Outgassing was also part of evaluation when the plastic compound figure was unknown

- Whenever no Single wafer lot was assured then TID and Life test sampling was increased by 40%

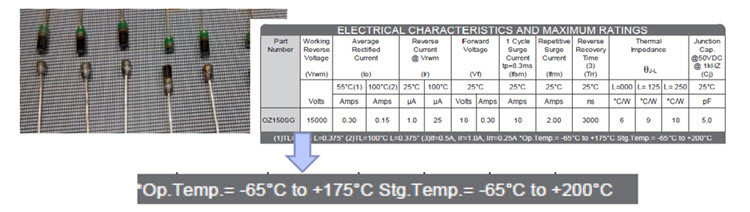

Case of OZ150, Wrong DATA in Data Sheet: after 1 thermal cycling among 85°C to -40°C , 49 out 72 samples failed “structurally”

Manufacturer replied that they were told about similar failure by one other user and they had recently updated the data sheet with a tighter temperature range (-40 °C to + 70 °C ) and with the warning that this part should not see thermal cycling.

OZ150 rejected for flight.

Replaced by RZ677 (thineed glass version of OZ150)+ parylene coating that passed the screening and evaluation

Photonic parts in Mars exploration related programmes

REMS General Topics:Rover Environmental Monitoring Inspection

- Temperature Range (-135ºC to +70ºC)

- Optical setup characterization:

Environmental Tests:

- Temp range: -135ºC to +105ºC

- Radiation neutrons, gamma, protons, etc..

- Life Test to simulate the day-night cycles

- 600 cycles -130ºC to +15ºC (Winter cycles)

- 1410 cycles -105ºC to + 40ºC (Summer cycles)

- Full characterization of UV Photodiodes

- From -135ºC to + 105ºC with steps of 10ºC

- Linearity

- Angle of Incidence variation

Combined Radiation and Temperature Test JUICE Mission

Characterization at extreme low temp: Cryogenic gamma radiation for JUICE -230 °C Gamma rad till 125 Mrad.

Combined temperature and radiation Low Energy Proton EffectsJonathan Pellish

One of the conclusions: CMOS nodes at and below 90nm have identified as sensitive to low-energy proton direct ionization.

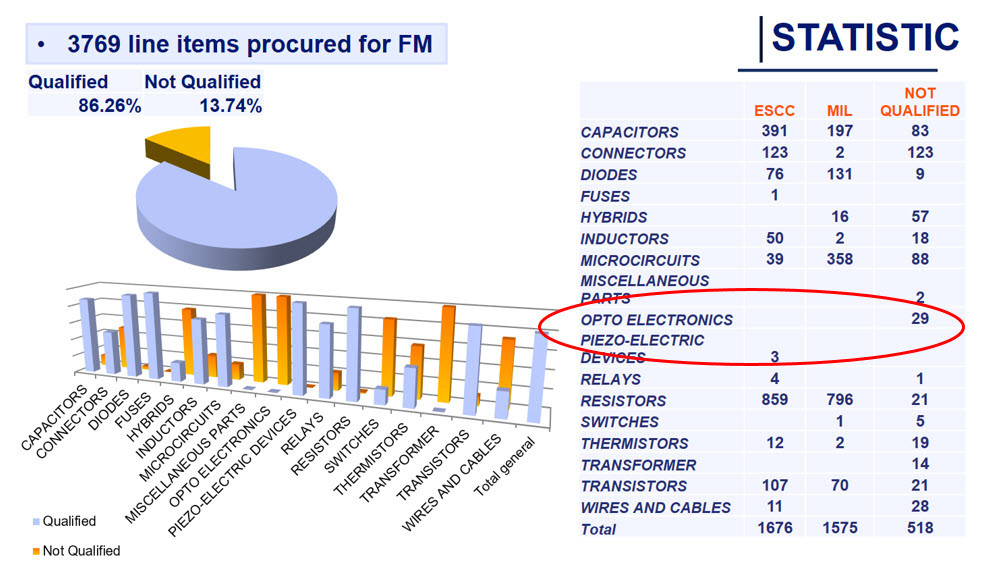

Constellations

Extreme environments:

JUICE (JUpiter ICy moons Explorer)

EUCLID (Geometry of the dark Universe)

LISA (Gravitation waves)

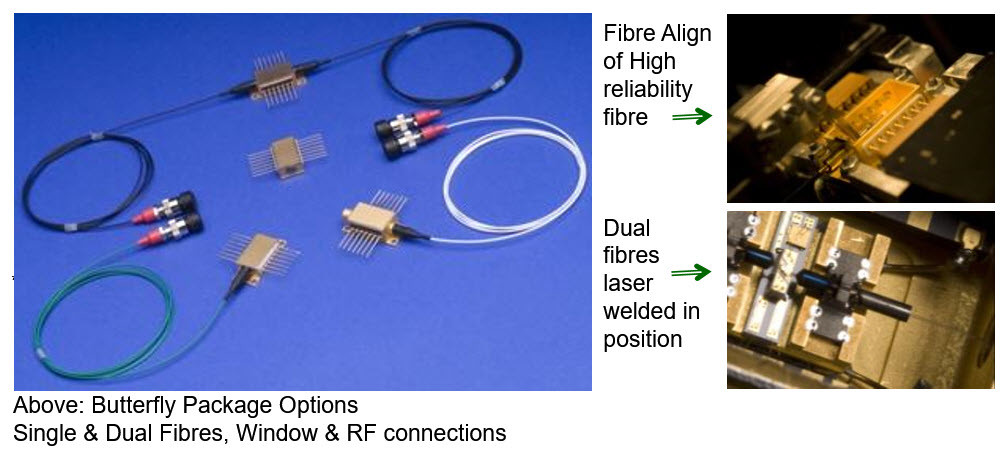

Custom package for space application

Optocap, turn-key packaging services enable our customers to reduce development and manufacturing costs, accelerate time to market and reduce risk with new product developments.

Our expertise in packaging solutions spans the full product life-cycle: from design through prototyping, process optimisation, product qualification, failure analysis, volume manufacturing and transfer to low-cost volume manufacture.

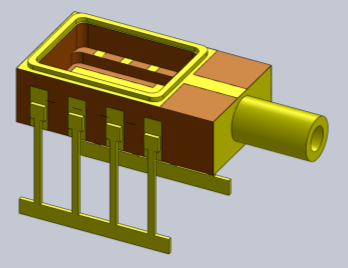

Space Qualifiable* MiniDIL Module

Modified Ceramic miniDIL Package: Same footprint in x, y dimensions. Integrating key features of Optocap’s 14 pin butterfly package, such as laser welded fibre alignment. No TEC included.

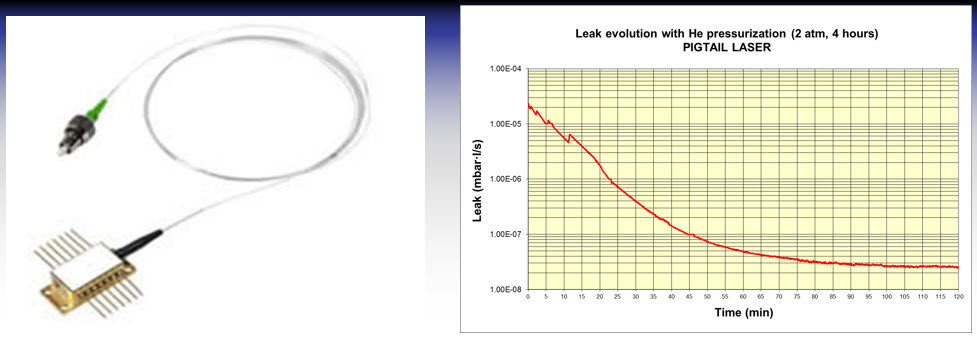

Pigtail Optical Components He leak Test

Hermeticity Test: Standard He Leak Test is very difficult or destructive for pigtailed Optical Components due to the absortion of He by the fiber.

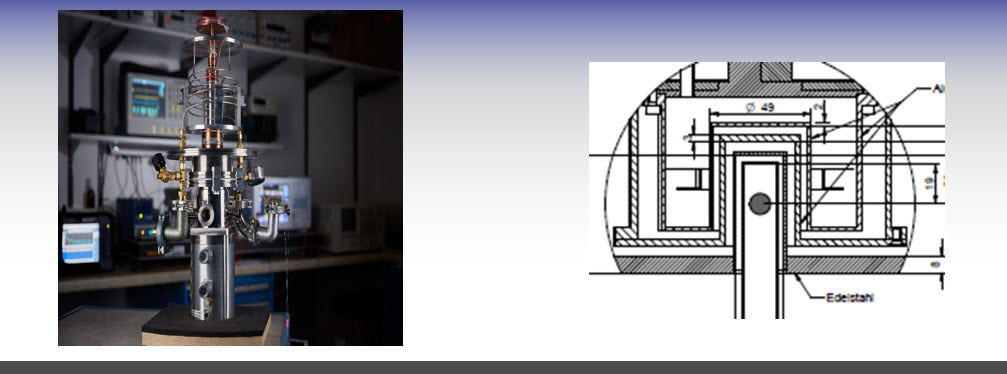

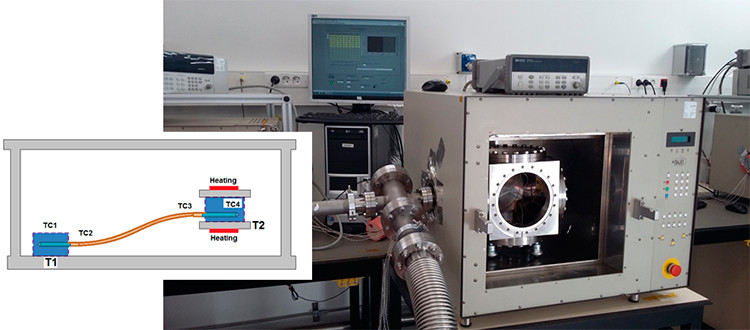

Image Sensor Thermal Strap Characterization

Thermal Vacuum setups: Thermal Vacuum and characterization at liquid nitrogen temp range

- Image sensor dissipation straps

- Vacuum tests from -180 ºC to more than 200 ºC.

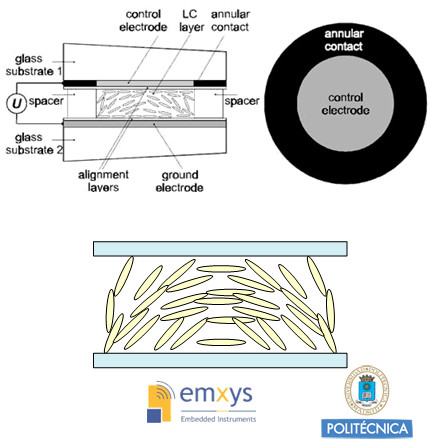

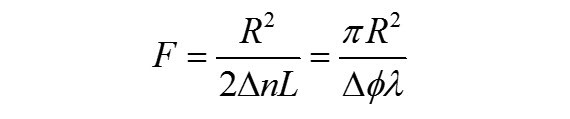

POE Project

Programmable Optical Element: Tunable Lens- Lenses are made by generating a lens profile in the switching of the LC

- Most LC lenses work for one polarisation only

- The profile of the lens is tuned by changing the electric field profile

- The focal length can be cast as:

- F varies with the wavelength as 1/Dn