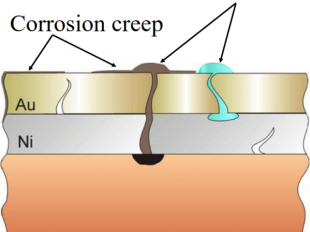

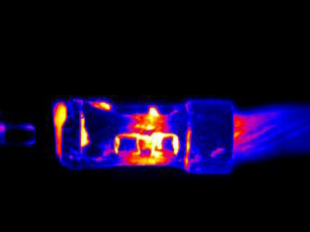

Crimped connectors are extensively present in EEE systems because of the good performance and easier installation at reduced dimension. Due to the key role played, they are required to have high durability even under harsh operating conditions. In the case of unexpected/early...

Tag - Method ECSS-Q-ST-70-26C Rev1.

The Method ECSS-Q-ST-70-26C Rev.1. is a Standard that defines the technical and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based a Crimped Connectors.

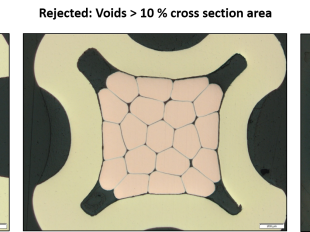

The Standard defines acceptance and rejection criteria for high-reliability manufacture of surface-mount and nixed-technology circuit assemblies intended to whithstand a normal terrestrial conditions and the vibrational g-loads and environmental imposed by space flight.

The proper tools, correct materials, design and workmanship are included to permit discrimination between proper and improper work.