Crimped concertos are extensively present in EEE systems because of the good performance and easier installation at reduced dimension. Due to the key role played, they are required to have high durability even under harsh operating conditions. In the case of unexpected/early failure, a thorough diagnosis and deep understanding of the main failure causes are the starting point to preclude future occurrence and improve the system reliability. Therefore, the present post gathers the main failure mechanisms in crimped connectors and indicates some the characterization tools used for the suitable failure analyses.

to the key role played, they are required to have high durability even under harsh operating conditions. In the case of unexpected/early failure, a thorough diagnosis and deep understanding of the main failure causes are the starting point to preclude future occurrence and improve the system reliability. Therefore, the present post gathers the main failure mechanisms in crimped connectors and indicates some the characterization tools used for the suitable failure analyses.

IEC Electropedia

Failure mode: “Manner in which a failure occurs. A failure mode may be defined by the function lost or other state transition that occurred.”

Failure mechanism: “Process that leads to failure. The process may be physical, chemical, logical, or a combination thereof.”

Failure cause: “Set of circumstances that lead to failure. A failure cause may originate during specification, design, manufacture, installation, operation or maintenance of an item.”

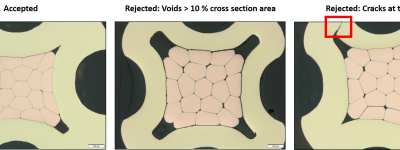

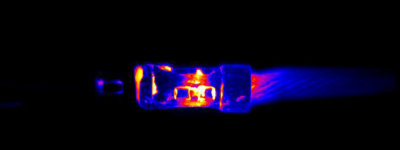

Due to the functionality, large contact resistance in excess of the threshold indicated by the specification and/or abnormal heating are main failure modes of any types of connectors. According to the literature1-5 typical failures in crimpred connectors can be ascribed to one of the following factors.

- Stress relaxation (Creep and recrystallization)

- Under/over crimping

- Galvanic

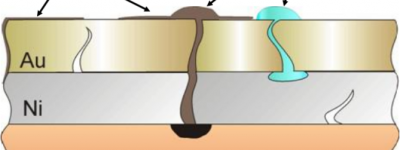

- Pore corrosion

- Surface contamination

Typical failures in Crimpred Connectors

Contact us

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019