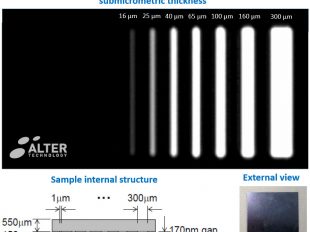

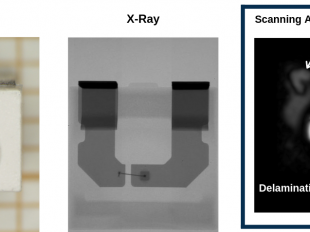

Scanning Acoustic Microscopy (SAM) has proved to be the most effective tool for the non-destructive detection of very thin (even below 200 nm of thickness) internal anomalies (delamination, voids, cracks, and foreign material) within ceramic capacitors and other EEE parts

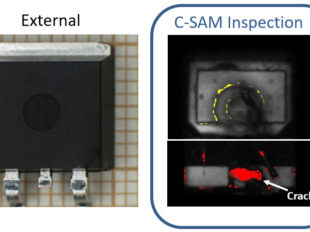

Package crack/void between non-connected terminals is a critical anomaly in plastic encapsulated parts. This is so as these can turn into a conductive path and lead to catastrophic failures. In this regard, Scanning Acoustic Microscopy (SAM) is the most effective non-destructive...

Micrometric-wide internal features of sub-micrometric thickness can be easily detected in our recently upgraded instrument. The high lateral resolution is within the current state of the start in the non-destructive inspection of deeply embedded objects.

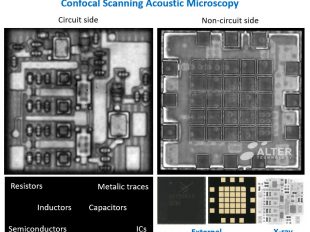

Hybrid microelectronics within plastic packages are comprehensively inspected thanks to the con-focal resolution provided by the scanning acoustic microscopy technique.

High-current low dropout regulator encapsulated in a TO-263 package is inspected by confocal scanning acoustic microscopy (C-SAM). Probe frequency and inspection procedure is adapted to the internal structure of this plastic encapsulated microelectronic part.

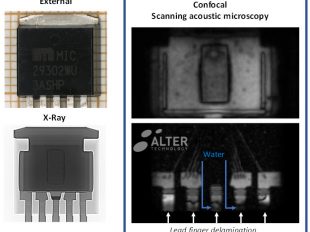

An Infra-red led emitter is inspected by scanning acoustic microscopy. Probe frequency is adapted to the characteristics of the system. In this case, considering the large thickness of the package a 50 MHz transducer is used. Our phase inversion algorithm identifies and...