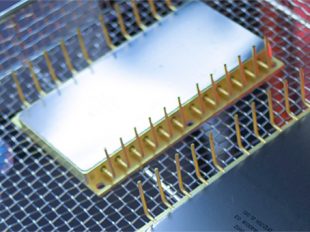

Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts and packages. One particular use of this analysis is the detection of prohibited materials, especially in the lead finish, to identify...

The purpose of this test is to verify that the markings on component parts will not become illegible when subjected to solvents (e.g. during the board cleaning process after parts assembly) or during normal handling, and that the solvents employed for the test will not cause...

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as presence of foreign objects, improper interconnecting wires, inhomogeneities in materials...

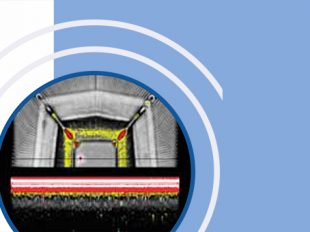

Scanning Acoustic Microscopy (SAM) is an inspection that uses focused sound to investigate, measure, or obtain an internal image of an object. It is commonly used in failure analysis and non-destructive evaluation. The semiconductor industry has found the SAM, particularly the C...