The objective of life testing is to evaluate whether failures caused by wear-out are likely to occur during the product lifetime and thus to estimate compliance of the device with the long-term reliability requirements.

Environmental testing provides a useful tool for evaluation, qualification and screening of EEE components for high-reliability applications. Various types of stresses can be applied to the products in a controlled manner thus allowing to accelerate the appearance of latent...

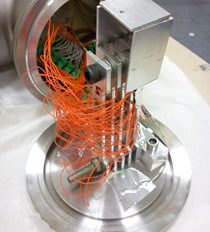

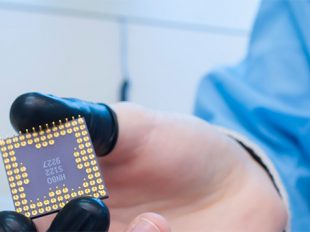

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) with the acquisition document. The following aspects should be considered: Marking Aspect of Materials Workmanship Sealing Leads Feedthroughs

is performed to evaluate the reliability of non-hermetic packaged solid-state devices that are likely to encounter humid environments during normal (ambient) operation. Also known as Pressure Cooker Test (PCT) or Unsaturated Pressure Cooker Test, the purpose of HAST is to...