External Visual Inspection

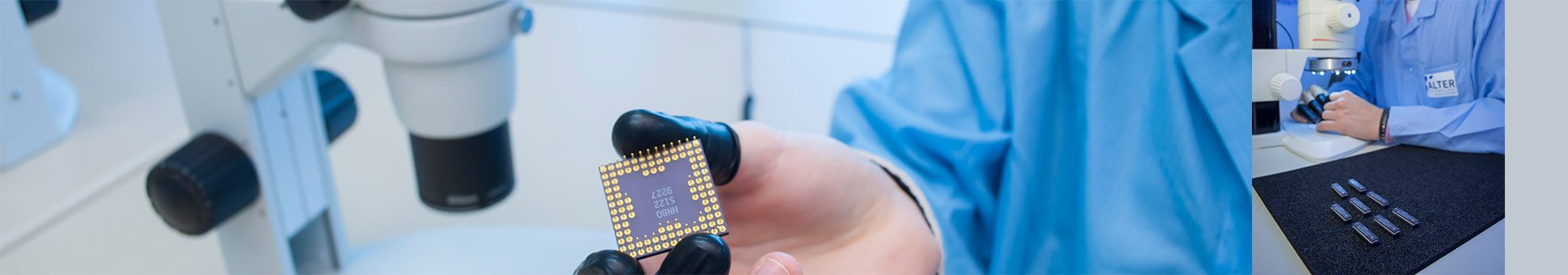

Consists in a non-destructive optical inspection. Binoculars with magnification between 1x and 60x and with a relatively large and accessible field of view are employed for this purpose.

FIGURE: External visual inspection at Alter Technology

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) with the acquisition document. The following aspects should be considered:

- Marking

- Aspect of Materials

- Workmanship

- Sealing

- Leads

- Feedthroughs

The external visual inspection is usually the key tool to assess the quality of parts, e.g. during a customer source inspection (Buy-off). Additionally, this inspection is of great relevance and also especially indicated for such large test sequences as 100% screening, qualification and evaluation testing, counterfeit investigation and many others. It is also utilized to inspect damage caused by handling, assembly and/or testing of the packaged device.

At Alter Technology we count on a highly trained team focused on these inspections and having all the necessary knowledge and understanding of the test methods used for space systems, such as:

- External Visual Inspection Electronic Components | EEE Parts - 9th December 2015

- Internal Visual Inspection Electronic Components | EEE Parts - 9th December 2015

- Penetrant Dye Gross Leak Electronic Components | EEE Parts - 9th December 2015