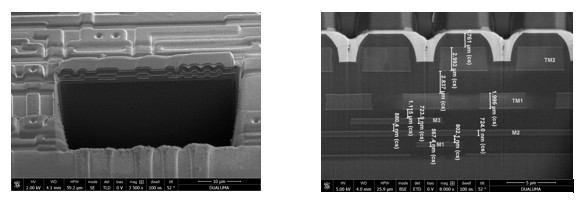

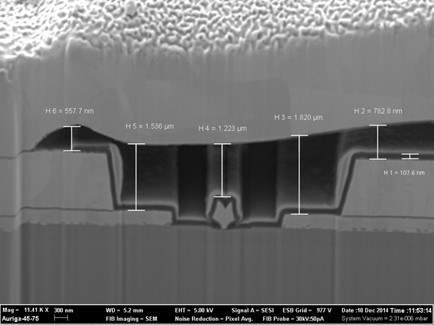

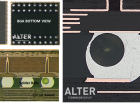

Focused ion beam, also known as ion milling, is a technique used particularly in the semiconductor industry and materials science for site-specific analysis, deposition and ablation of materials. Since it is destructive to the part, FIB technology is used for micro-sectioning in DPA and also in failure analysis. An FIB setup is a complement to the SEM equipment, but while the SEM uses a focused beam of electrons to image the sample in the chamber, an FIB setup uses a focused beam of ions instead. When the high-energy gallium ions strike the sample, they sputter atoms from the surface. Gallium atoms will also be implanted into the top few nanometers of the surface, and the surface will be made amorphous. Because of the sputtering action of the ion beam, the FIB can be used to locally remove or mill away material.

This is a very accurate method of die micro-sectioning, allowing measuring the different layers of microcircuits.

FIB Micro-sectioning

The FIB micro-sectioning is performed in accordance with the applicable test methods such as MIL-STD-883 methods 2010 and 2018. The Risk Assessment and Mitigation, NASA MSFC Technical Standard 3619 recommends the use of this technique in order to identify construction anomalies and to determine characteristics of the die and internal part structures.

Focus Ion Beam is a must-have technique not only for wafer acceptance, design changes validation and failure analysis but also for validation of the internal die characteristics capable to show any potential long term reliability issue, valid not only for integrated circuits but also especially applicable on MEMS.

Standars Tests PDF Files

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019