Cross-sectioning

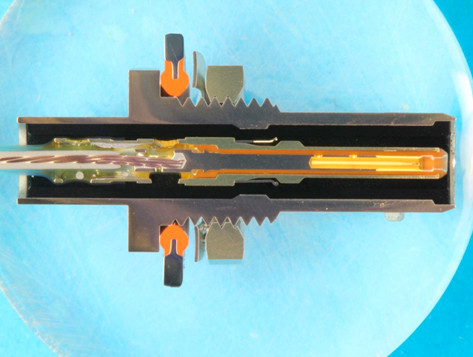

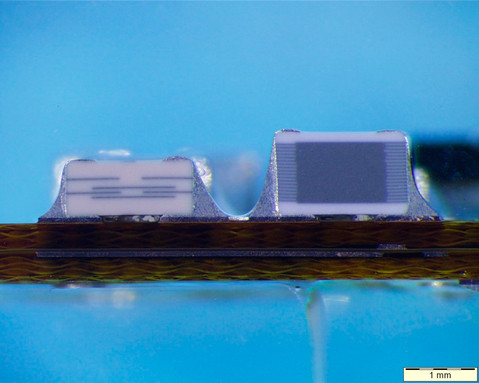

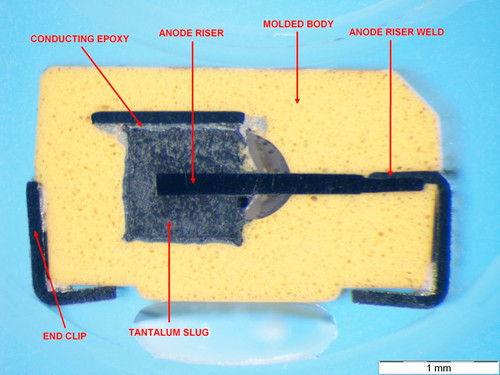

The cross-sectioning process provides access to the device internal structure, its materials, and design. Such components as diodes and capacitors and silicon dice are often subjected to cross-sectioning to detect the defects which could not be found using other testing techniques.

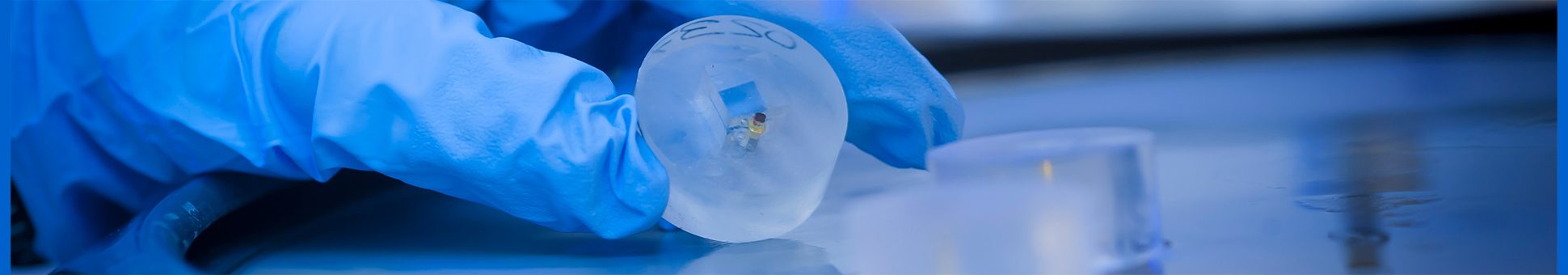

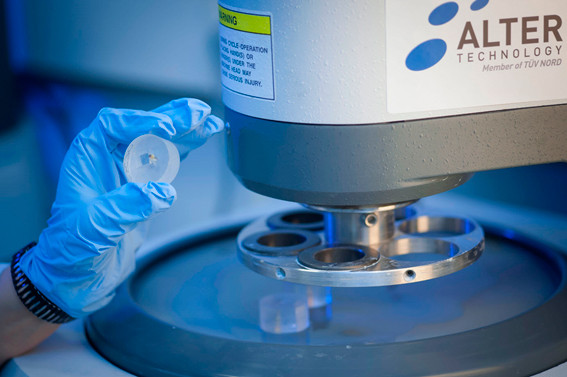

FIGURE: Cross – sectioning on a connector at ALTER TECHNOLOGY (grinding process).

Cross-sectioning generally involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the surface so exposed. The main purposes of these steps are exposed to the hereafter.

Mounting:

- To hold the sample and their internal elements together during the sectioning process.

- To provide a means of holding the sample during grinding and polishing operations.

- To provide a convenient means of positioning the sample on the microscope stage for examination.

The purpose of grinding is to quickly reach a broad region of interest. This enables the exact area of interest to be reached by subsequent slower polishing techniques in a reasonable period of time. Grinding is carried out by using silicon carbide paper disks mounted on horizontal rotary grinding wheels. A continuous flow of water is used for cooling and cleaning the wheels.

A key element in the performance of cross-section is the ability of the inspector to detect and identify problems and non-conformances of the products. An extensive experience in the technologies examined, knowledge about acceptance criteria and cumulated know-how are a prerequisite for a proper test execution.

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019