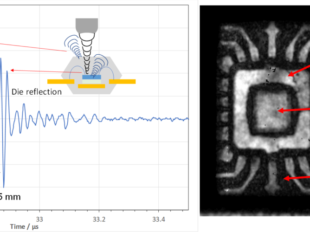

Scanning Acoustic Microscopy (SAM) has proved to be the most effective tool for the non-destructive detection of very thin (even below 200 nm of thickness) internal anomalies (delamination, voids, cracks, and foreign material) within ceramic capacitors and other EEE parts

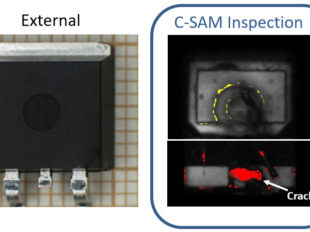

Package crack/void between non-connected terminals is a critical anomaly in plastic encapsulated parts. This is so as these can turn into a conductive path and lead to catastrophic failures. In this regard, Scanning Acoustic Microscopy (SAM) is the most effective non-destructive...

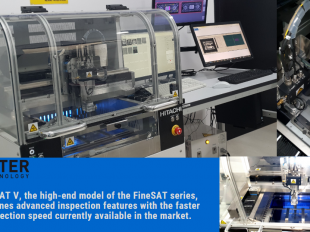

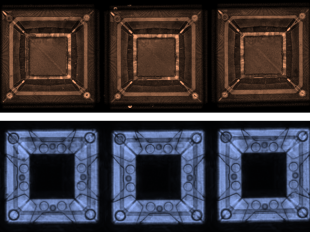

High-resolution inspection of plastic encapsulated systems with complex internal architectures requires of confocal imaging techniques to block out-of-focus features that otherwise impair the resolution and the image quality.

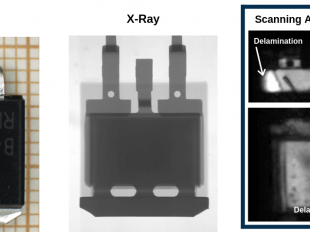

Non-destructive testing methods are critical for the screening, inspection and failure analysis of plastic encapsulated and other EEE systems. Typical non-destructive testing activities involving EEE parts are grouped in three main categories: • Functional inspection (electrical...