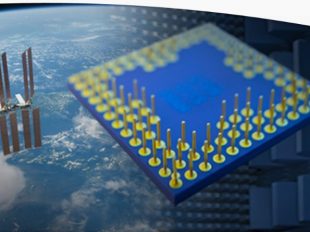

Flip chip assembly techniques bring a wide range of benefits: A reduced parasitic interconnection between the semiconductor die and package. Provides a high final assembly integrity density. Minimize the interconnection length, providing better electrical performances...

Tag - flip chip

Optocap