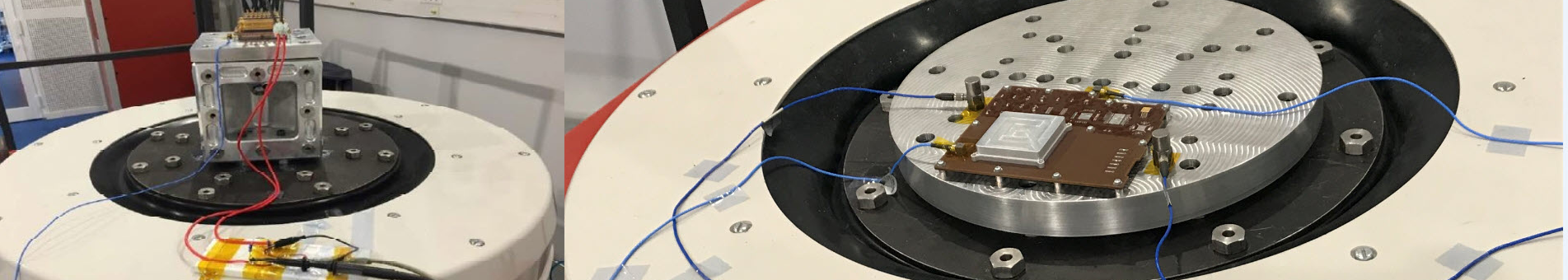

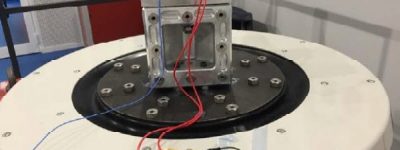

Vibration Testing is performed to validate the reliability, performance and structural integrity of a device during its transportation and useful life, avoiding life failure in space. Vibration Testing mimics the conditions such as the one during a rocket launch. Some devices have mechanical parts that may be sensitive to testing and therefore to have a malfunction in its final application.

Vibration Testing is a very specialized field where Alter Technology is a high qualified laboratory. With a Vibration Test you can comply with customer qualification requirements, improve your product reliability, estimate life expectancy and perform package testing.

Standards we test to:

- MIL-STD-883 Methods 2002, 2005, 2006, 2007, 2026.

- MIL-STD-750 Methods 2016, 2046, 2051, 2056, 2057.

- MIL-STD-202 Methods 201, 204, 213, 214.

- ESCC 3401 Para 9.11.2, Para 9.11.3.

The team of engineers working in our vibration laboratory has experience in:

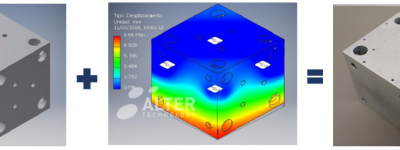

- Design and analysis of the necessary tools for the fixation of components to the shaker platform to ensure that the tool does not introduce disturbances to the test due to its resonance frequencies.

- Analysis and testing of different types of vibration tests: sine, random and shock (with SRS table and shaker).

- Additional capabilities include monitoring electrically of the device to complete the functionality during the test.

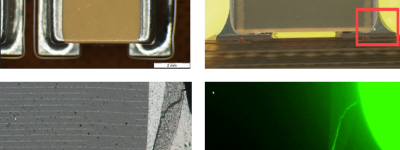

Vibration tests are also carried out as part of the test sequence of the PCB and SMD verification test-programmes according to the ESCC specifications.