Ground level testing for electronic device and material

Talk summary:

Space is a harsh environment due to vacuum, UV, temperature, vibration and radiation…etc. Before landing a space vehicle, devices and materials have to be tested at ground level in order to estimate the effect of all these parameters to know about irradiators.

This is why, it is essential, in order to assure a well control, understanding and reactivity to dispose at home of facilities to perform these tests. The aim of this presentation is to give you a global overview of the equipment available at TRAD to respond to this need.

During this presentation our facilities will be presented, such as:

- Cobalt 60 for Total Ionising dose Test

- VESPA (Vacuum Electron Irradiation Facility For SPAtialization)

- Solar simulator UV irradiation

- Thermal cycling

- SWIPI (Solar Wind Protons Irradiation)

- De-capping facilities

Pierre GARCIA is graduated from Montpellier University with a PhD in electronics, France, in 2009.

After his graduation he joined TRAD in Toulouse, France, as a radiation test engineer, he is now a Test team manager.

With 10 years of experience in radiation characterization. He manages a wide variety of electronic project including analog, digital, and mixed signal devices.

The dedicated irradiators and facilities for material studies

Material qualification & characterization facilities

TRAD Material Laboratory

- Up to 15 suns

- In-situ monitoring (UV flux and sample temperature)

- Irradiation area: 60 x 60 mm (10% homogeneity)

- Chamber pressure < 10-5 mbar

- In accordance with ECSS-Q-ST-70-06C

- Inert atmosphere (N, Ar or He)

- Temperature range: -170°C to +400°C

- Rising and decreasing speed: up to 20°C/min

- Chamber dimensions: 35 x 33 x 33 cm

- In-situ electrical measurements

- In accordance with ECSS-Q-ST-70-04C

- Chamber pressure < 10-5 mbar

- Temperature range: -190°C to +190°C

- Rising and decreasing speed: up to 10°C/min

- Chamber dimension: 1 plate of 20 x 11 cm

- In-situ electrical measurements

- In accordance with ECSS-Q-ST-70-04C

- Chamber pressure < 10-6 mbar

- Temperature range: -170°C to +200°C

- Rising and decreasing speed: up to 10°C/min

- Chamber dimension: 2 plates of 15 x 30 cm

- In-situ electrical measurements

- In accordance with ECSS-Q-ST-70-04C

- Energy: 300eV to 5keV

Adapted to ageing tests for materials that are directly exposed to space environment (paints, coatings, polymers…)

- Chamber pressure < 10-6 mbar

- Temperature range: -170°C to +200°C

- In-situ electrical measurements

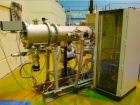

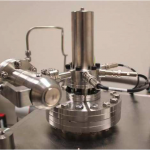

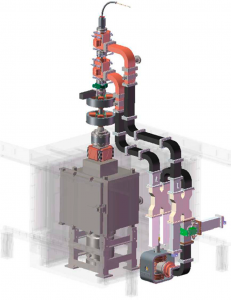

VEISpa: electron irradiation facility

Vacuum Electron Irradiation facility for Spatialization

- Type: LINAC

- Energy: 1 to 4 MeV

- Low current mode: 6 107 cm-2.s-1

- High current mode: 3 1011 cm-2.s-1

- Irradiation area: 30 x 30 cm

- Vacuum < 10-5 mbar or inert atmosphere

- Temperature range: -150°C to +200°C

- In situ-electrical measurements

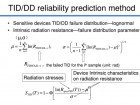

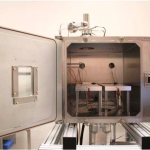

GAMRAY: Co60 irradiation facility

Panoramic Cobalt-60 source Gamma irradiation for TID testing.

- 14.8 TBq on 04-Sept-15

Irradiation Room

Control Room

- 2 main energies at 1.17 and 1.33 MeV

- Dose rate: 10rad(Si)/h to 4krad(Si)/h (without shielding)

- Regulated temperature: 20°C (±2°)

- Useful irradiation volume: 45 m3

De-capping facilities

Mechanical de-capping and Chimical de-capping

Laser test bench for SEE characterization

Pulsed Laser Test

- Laser Nd:YAG with wavelength 1064nm

- Pulse duration : 790ps

- Can be triggered from single shot to 50kHz frequency pulse

- Energy : 0.06 – 135.9 nJ/pulse

- Spot size: 1.8, 2.6 and 8μm

- 3 motorized linear stages (X, Y, Z), resolution 0.3μm

- Tests performed on front or back side scanning of the delidded device

- Efficient tool for the designers

- Help to Improve the hardening process

Californium test for devices sensivity assessment

Californium Test

- Mean LET = 43 MeV.cm².mg-1

- Mean Range = 14 μm

Tests performed under vacuum on delidded device

Test bench evaluation/validation or SEE sensitivity assessment

Download or read the full report here

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019