Evaluation / Qualification

During the Evaluation phase, components/technologies can be extensiveli characterised and margins determined.

If the evaluation is successful we can then proceed with Qualification, on components produced strictly as defined in the final PID (Process Identification Document) and from a given lot (actually, the first production lot).

Once qualified, the component is listed in the QPL (Qualified Part List).

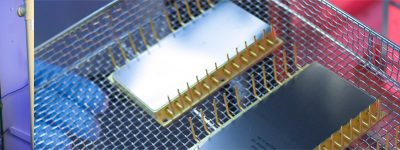

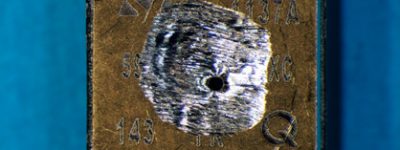

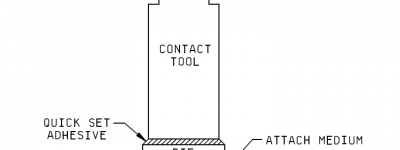

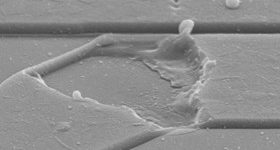

- Constructional Analysis

Test performed to validate the quality and reliability of the selected part. They will also provide information about how using the parts and their expected performance.

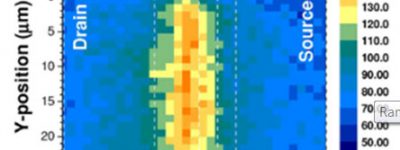

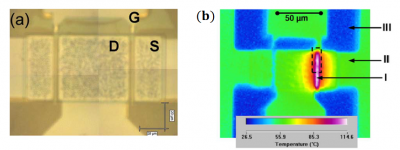

- Electrical testing

Experiment designed to confirm that a device meets specific requirements, from the electrical point of view.

These requirements can be aspects related to the total or partial functionality of the device and / or properties and characteristics thereof.

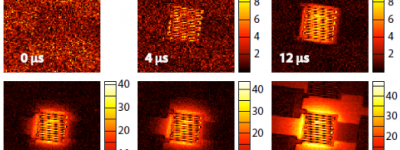

- Environmental testing

Environmental testing is the measurement of the performance of components under specified environmental conditions, such as: Standard temperature test, from cold to heat testing, in dry and damp atmospheres and adjustable temperature change rate: thermal cycling, thermal shock air to air, thermal shock liquid to liquid, etc.