Substrate Attach Strength – Die Shear Strength

The purpose of the test is to determine the strength of the element attachment system when subjected to force in the Y1 axis, and thus to determine the integrity of materials and processes used to attach semiconductor die or surface mounted elements to package headers or other substrates. The implementation of this test includes material evaluation and process control.

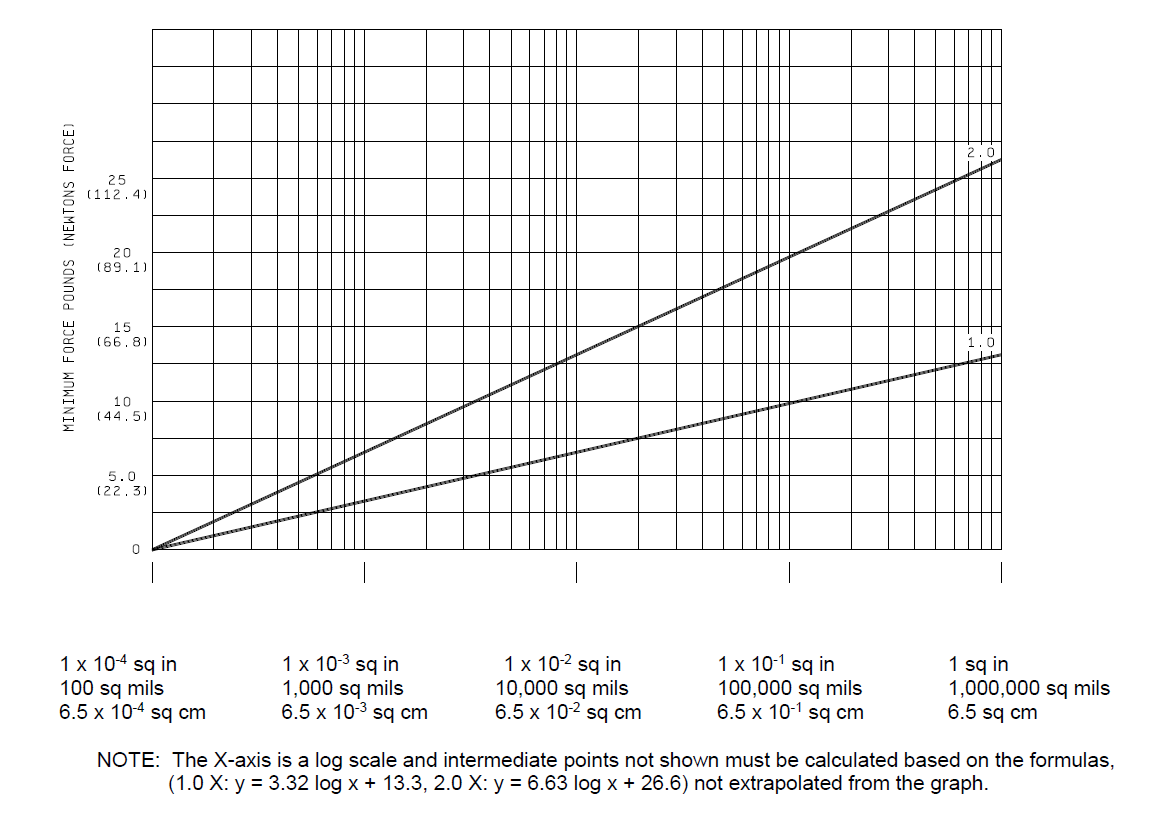

The test consists in applying a force proportional to the area of the die to be tested (with an accuracy of ±5%) using a tensile strength tester. The determination of acceptability of parts is based on the force applied to the die, on the type of failure resulting from this application of force (if any failure occurs) and on the visual appearance of the residual die attach media and substrate/header metallization.

In order to execute the test, the following characteristics of the equipment used must be taken into account:

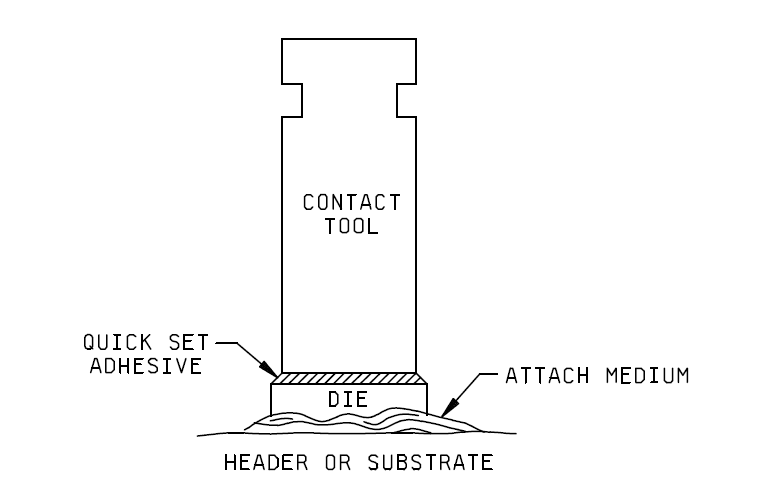

• A range of replaceable die contact tools such that each contacting surface shall be 60 to 100 percent of the area of the die under test.

• Provision to ensure that the die contact tool is held perpendicular to the die mounting plane of the header or substrate.

• A rotational capability between the die contact tool and substrate holding fixture.

The defects must be then examined under an optical microscopes (binocular) under sufficient magnification (minimum 10X) and lighting which permits visual observation of the die and die contact tool interface during testing.

The test is conducted by applying a force sufficient to shear the die from its mounting or equal to twice the minimum specified shear strength whichever occurs first. The separation of the die from the header/substrate occurring at a force value less than that specified in the inspection test method constitutes a failure.

This test method is based on: MIL-STD-883 METHOD 2027.2

- SOLAR CELLS - 30th July 2018

- Radiographic Inspection 3D X Ray – 2D | Hi Rel Electronics Parts - 20th January 2016

- Substrate Attach Strength – Die Shear Strength | EEE Parts - 9th December 2015