Glassivation Integrity

This test is performed to verify the structural quality of the glassivation layer in aluminium metallized semiconductor devices or microcircuits. The glassivation layer is a deposited dielectric film (e.g., CVD, sputtered of electron beam evaporated glass or nitride, etc.) and its good condition is essential to avoid such problems as electromigration.

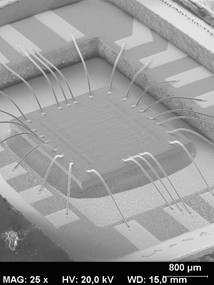

General view of a die

The sample is immersed in an aluminium etching solution, in accordance with MIL-STD-883 TM 2021. After etching, the final optical inspection at high magnification is performed using a scanning electron microscope. If the glassivation layer has no defects, no damage in the metallized device will be observed. The metal being etched will mean that the glassivation layer is either flawed or not duly protective and may lead to a failure.

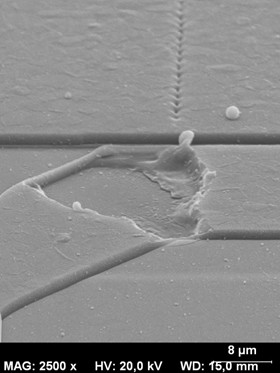

Defective glassivation

Lot rejection shall be based on the appearance of etched aluminium at any location other than along the edges immediately adjacent to intentionally unglassed areas (e.g., bonding pads, die edge, scribe line, etc.) as shown on figures 2021-1 to 2021-7 of MIL-STD-883, method 2021.

The defects detected in the glassivation layer shall be categorized as follows:

- Missing glassivation over aluminium (figure 2021-1 of MIL-STD-883 method 2011)

- Cracks in glass over aluminium (figure 2021-2 of MIL-STD-883 method 2011)

- Cracks in glass or improper glass coverage along edge of aluminium (figure 2021-3 of MIL-STD-883 method 2011)

- Pinholes in glass on top surface and edges of aluminium (figure 2021-4 of MIL-STD-883 method 2011)

Standar Test PDF File

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019