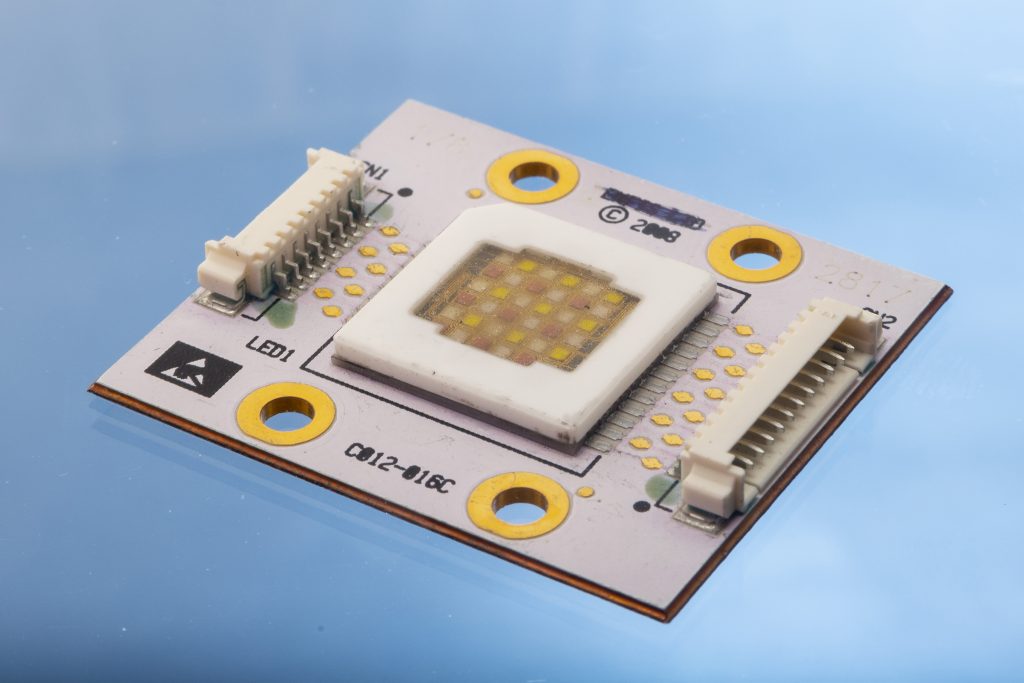

Why LED Chip-on-Board?

- Cost-effective alternative to incandescent and fluorescent light sources

- Increased life span and efficiency

- System integration, no user-serviceable parts

- The reduced total cost of ownership

- Customised array size and shape

- Application-specific wavelengths

- Increased life span and efficiency

- Chip-on-board vs. surface mounted LEDs:

- Low-pitch / higher density arrays

- Improved efficiency and heat dissipation

- No over-moulding material boosts light output

- Fewer interconnects reduce reliability risk

Why Alter Technology UK?

- Value Proposition

- Experienced LED CoB module provider

- The flexible and customisable platform

- Reduced time to market

- Product-specific experience and processes

- Established material supply chain

- Reduced technical risk

- Existing design and process knowledge

- Rapid prototyping on production tools

- Reduced cost

- No capex requirement for customer

- Volume manufacturing capacity

- >200K LED placements per month.

- Concept to a product:

- Substrate design & sourcing, ceramic, IMS, FR4.

- Sourcing tested & binned LED dies

- Optical and thermal modelling

- Full range of volume assembly services

- Functional test

- Characterisation

Assembly Capabilities

- Die Attach

- Ag epoxy stamping or dispense

- Sintering epoxy materials

- Soldering

- Pick from film/frame, waffle or gel pack.

- Flip-chip attach & Au stud bumping

- Wire Bond

- 17 to 50um Au ball bonding

- Plasma clean for improved adhesion

- Encapsulation Options

- Frame laser cutting and attach

- Glass cover attach

- Silicone encapsulation

- Dome attach

- Specialist processes for mixing and degassing

- QC checks

- Die shear and wire strength tests

- Placement accuracy measurements

Contact us for more information

Latest posts by Media ATN (see all)

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019