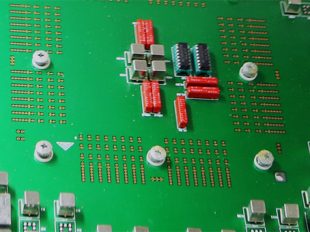

Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts and packages. One particular use of this analysis is the detection of prohibited materials, especially in the lead finish, to identify...

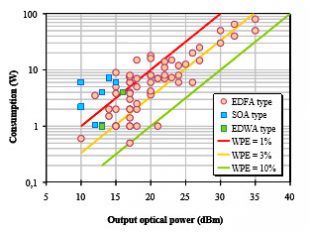

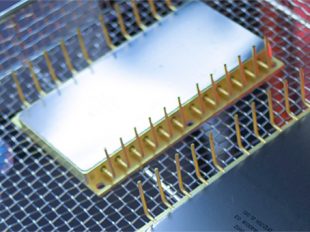

This paper describes the activities and results of an ESA-funded project concerned with the assessment of optical amplifier technologies and products for applications in fiber optic subsystems of future satellite payloads. On-board applications are briefly introduced, together...

The purpose of this test is to verify that the markings on component parts will not become illegible when subjected to solvents (e.g. during the board cleaning process after parts assembly) or during normal handling, and that the solvents employed for the test will not cause...

PIND ( Particle Impact Noise Detection Test ) testing is performed in order to detect the presence of loose particles inside a device cavity. Loose particle contamination is often caused by dirt, fibers, solder residues and other elements trapped inside the cavity during the...

This type of inspection is performed using an electron microscope which produces images of a sample by scanning it with a focused electron beam. Interaction between the electrons and atoms in the sample generates signals that contain information about the sample’s surface...

The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices.

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as presence of foreign objects, improper interconnecting wires, inhomogeneities in materials...

The purpose of vibration tests is to evaluate the effect caused on component parts by vibration in a specified frequency range. The samples are subjected to testing under different conditions, as described below, in accordance with the respective applicable standards. The test...