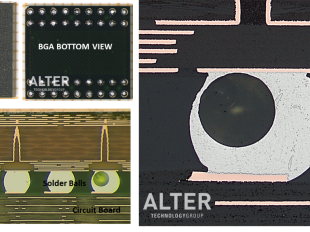

BGA device assembled to a PCB has been submitted to the ECSS verification programme following the guideline defined in the ECSS standard ECSS-Q-ST-70-38C.

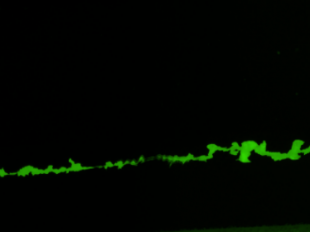

At Alter Technology, we can perform 3D characterization using Confocal Laser Scanning Microscopy and the world’s most integrated and flexible test equipment for nondestructive 3D dimensional characterization, helping designers to get in-depth information about their prototypes.

This type of inspection is performed using an electron microscope which produces images of a sample by scanning it with a focused electron beam. Interaction between the electrons and atoms in the sample generates signals that contain information about the sample’s surface...

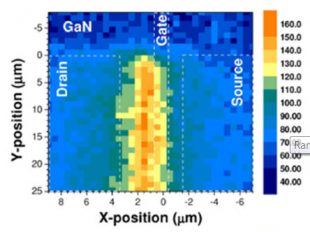

This analytic technique may provide both qualitative and quantitative information of the composition of a surface, i.e. identification of the elements and the element weights, respectively. The technique relies on the detection and spectroscopy of secondary radiation (X-Ray)...

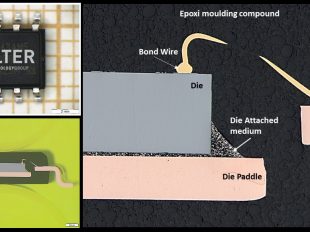

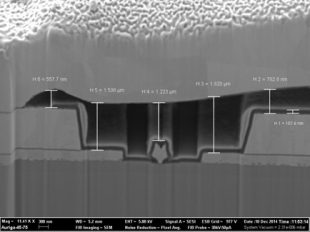

Focused ion beam, also known as ion milling, is a technique used particularly in the semiconductor industry and materials science for site-specific analysis, deposition and ablation of materials. Since it is destructive to the part, FIB technology is used for micro-sectioning in...