Radiation assurance test is very interesting, but also very complicated. It always needs joint efforts to find better solutions, and BMTI is looking forward to collaborating with related partners to do this.

The advent of the chirped-pulse amplification (CPA) technique has revolutionized the physics of particle accelerations. Compared to conventional accelerator, lasers can produce ultra short particle beams with high brilliance and broad energy spectrum. Moreover Laser technology...

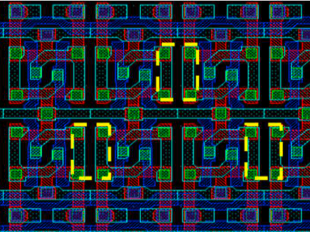

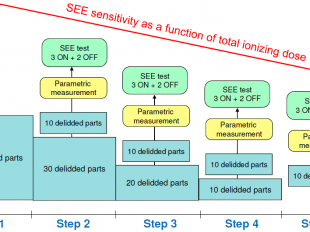

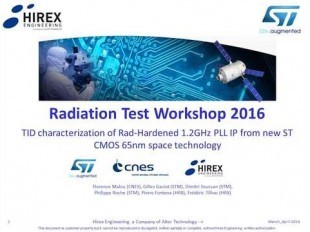

The Total Ionizing Dose (TID) radiation test on EEE parts involves a number of variables and processes which must be kept under control to ensure correct test execution and compliance with the used test method. From the test plan definition to the test report issue, proper...

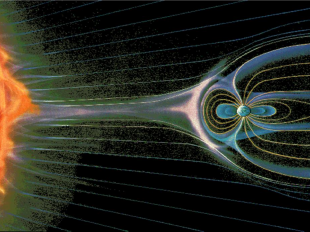

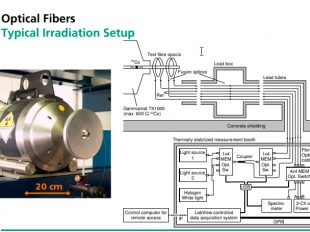

Space is a harsh environment due to vacuum, UV, temperature, vibration and radiation…etc. Before landing a space vehicle, devices and materials have to be tested at ground level in order to estimate the effect of all these parameters to know about irradiators. This is why, it is...

In space applications, optocouplers may need to work at very low temperatures. Under this low temperature operating conditions, the device degradation subjected to radiation exposure may show different behaviour compared to a standard radiation test under room temperature. The...