PIND ( Particle Impact Noise Detection Test ) testing is performed in order to detect the presence of loose particles inside a device cavity.

Loose particle contamination is often caused by dirt, fibers, solder residues and other elements trapped inside the cavity during the sealing process. Loose particles can be a cause of electrical anomalies (or other physical problems) which in their turn can cause abnormal functioning of the parts and affect their reliability.

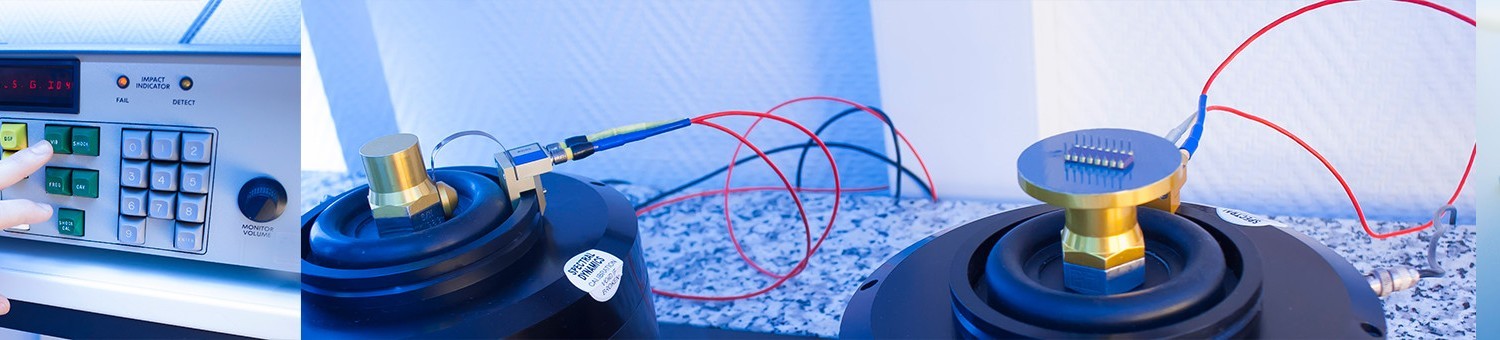

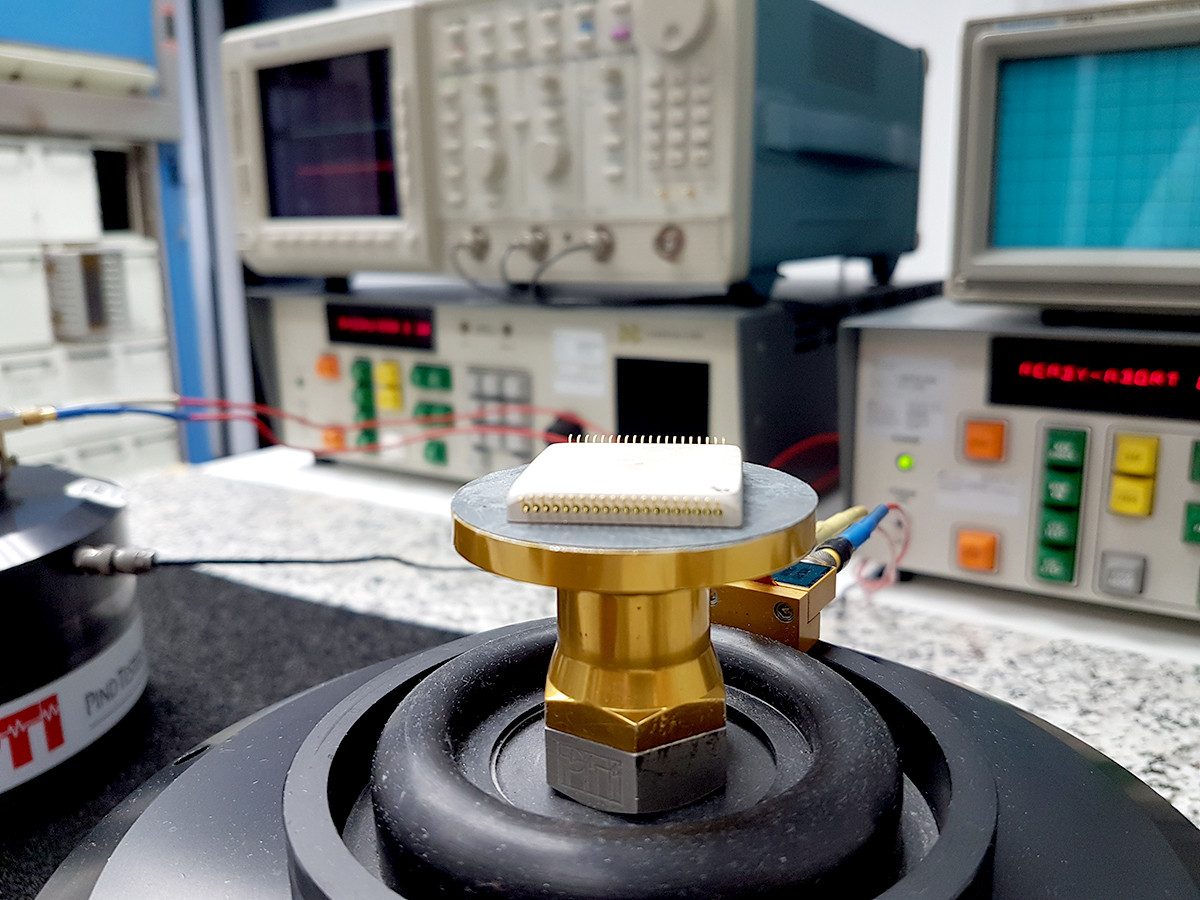

To perform the PIND test the device is adhered to the transducer head. The cavity resonance frequency (which depends on the dimensions of the sample) being previously calculated, the device is subjected to the vibration of that frequency. If the device contains loose particles of sufficient mass, they, upon impact with the case or elements within the case, excite the transducer and are detected.

Our PIND test system allows the frequency adjustment up to a maximum of 250Hz, and is capable of providing shock pulses up to 2000g.

- PIND test – Particle Impact Noise Detection | EEE Parts - 21st January 2016