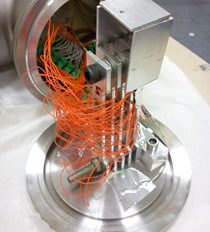

Electronic Components Thermal shock testing is performed to determine the ability of parts to function properly in an environment with sudden extreme changes in temperature. It is also used for accelerated testing during product evaluation and qualification process. Thermal...

Environmental testing provides a useful tool for evaluation, qualification and screening of EEE components for high-reliability applications. Various types of stresses can be applied to the products in a controlled manner thus allowing to accelerate the appearance of latent...

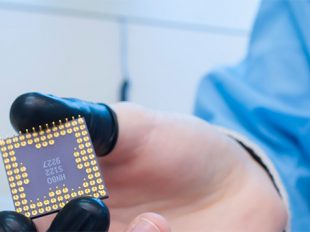

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) with the acquisition document. The following aspects should be considered: Marking Aspect of Materials Workmanship Sealing Leads Feedthroughs

This analytic technique may provide both qualitative and quantitative information of the composition of a surface, i.e. identification of the elements and the element weights, respectively. The technique relies on the detection and spectroscopy of secondary radiation (X-Ray)...

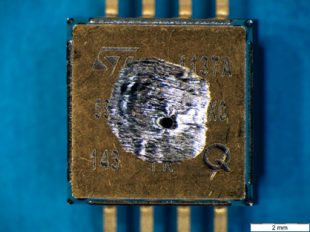

The aim of this destructive test is to demonstrate that the internal materials, design, construction and assembly of EEE parts are in accordance with the applicable acquisition document. This test can also be performed to examine unsealed devices prior to capping to verify that...

The purpose of the test is to determine the strength of the element attachment system when subjected to force in the Y1 axis, and thus to determine the integrity of materials and processes used to attach semiconductor die or surface mounted elements to package headers or other...

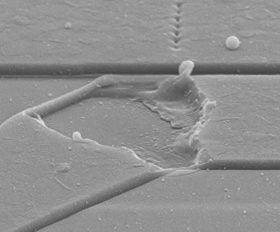

This test is performed to verify the structural quality of the glassivation layer in aluminium metallized semiconductor devices or microcircuits. The glassivation layer is a deposited dielectric film (e.g., CVD, sputtered of electron beam evaporated glass or nitride, etc.) and...

Penetrant dye gross leak test is used to identify leakage pathways within hermetic and non-hermetic devices, such as glass body devices or plastic encapsulated parts. The test provides a definitive view of the leak paths including cracks, voids, delaminations and other fractures.