Die Bonding Services

Die bonding is the process of attaching a die to substrate/package. Selection of the optimal die attaches material and process is based on a number of issues including thermal requirements, electrical requirements and mechanical stability.

Solder Die Attach

Alter Technology (formerly Optocap), has experience with a wide range of solder materials including soft and hard solders, Pb-free solders, Eutectic solders and solders for operation over a wide temperature range.

This knowledge is critical in supporting our customers in making the correct decisions on solder material selection for their product.

For many Opto, MEMS or Sensor devices fluxes can pose reliability concerns with contamination of the sensitive active regions of these devices. As a result, many of the solders attach processes at Alter Technology UK are based on a flux free solder process utilizing solder preforms or pre-tinned substrates with a subsequent Vacuum Reflow process, or reflow using Pulsed Heat-Stages with reducing or cover gas to prevent oxidation.

In order to use a solder attach process, the components require a compatible metal surface. Alter Technology UK can provide input on appropriate surface finishes.

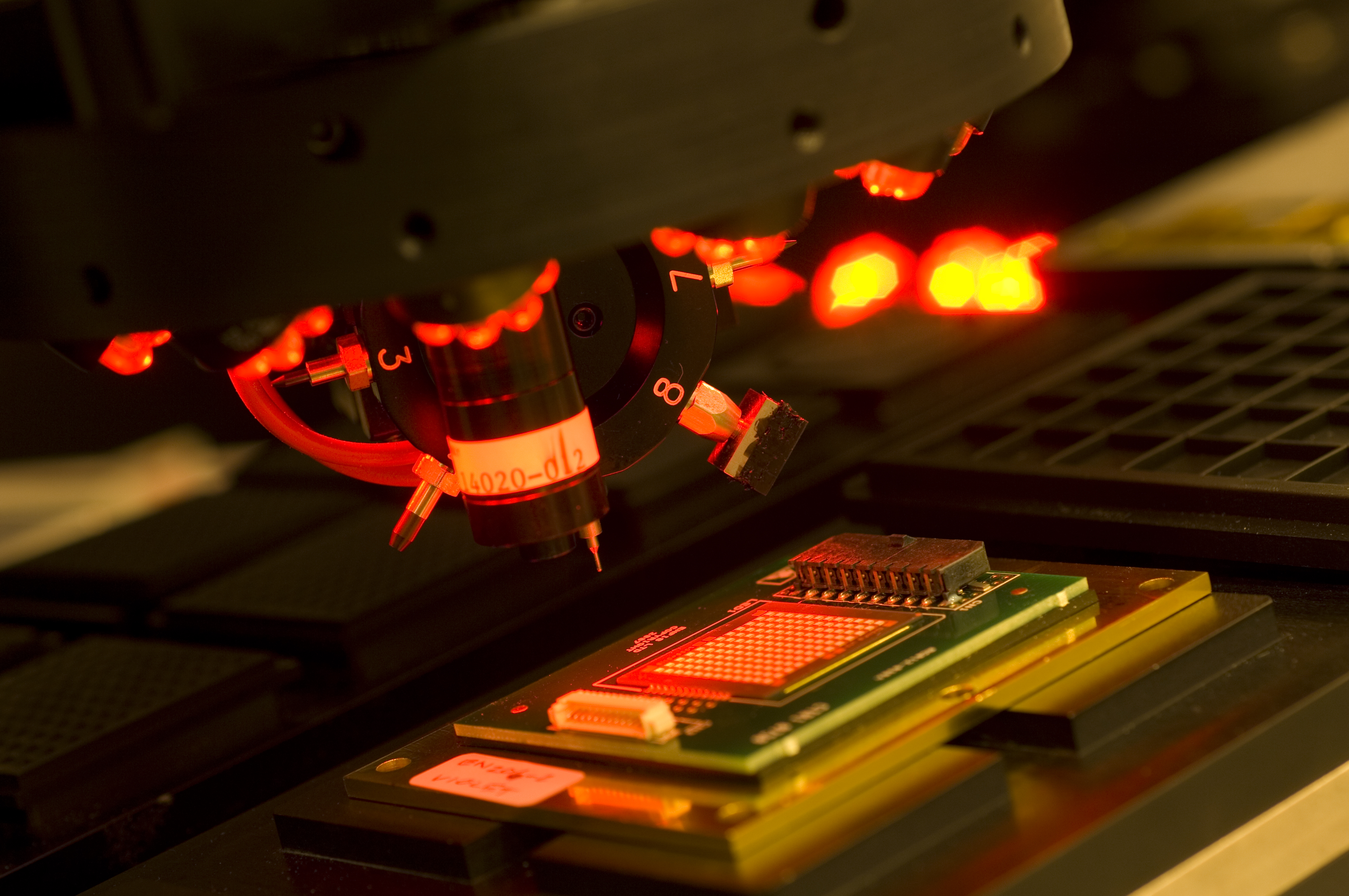

Solder pastes are screen printed onto substrates in patterns defined by custom designed stencils. Components are then pick and placed into the solder paste and reflowed using conventional IR reflow processes.

Alter Technology UK has experience with a wide range of solder materials including soft and hard solders, Pb-free solders, Eutectic solders and solders for operation over a wide temperature range.

Contact us for more information

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019