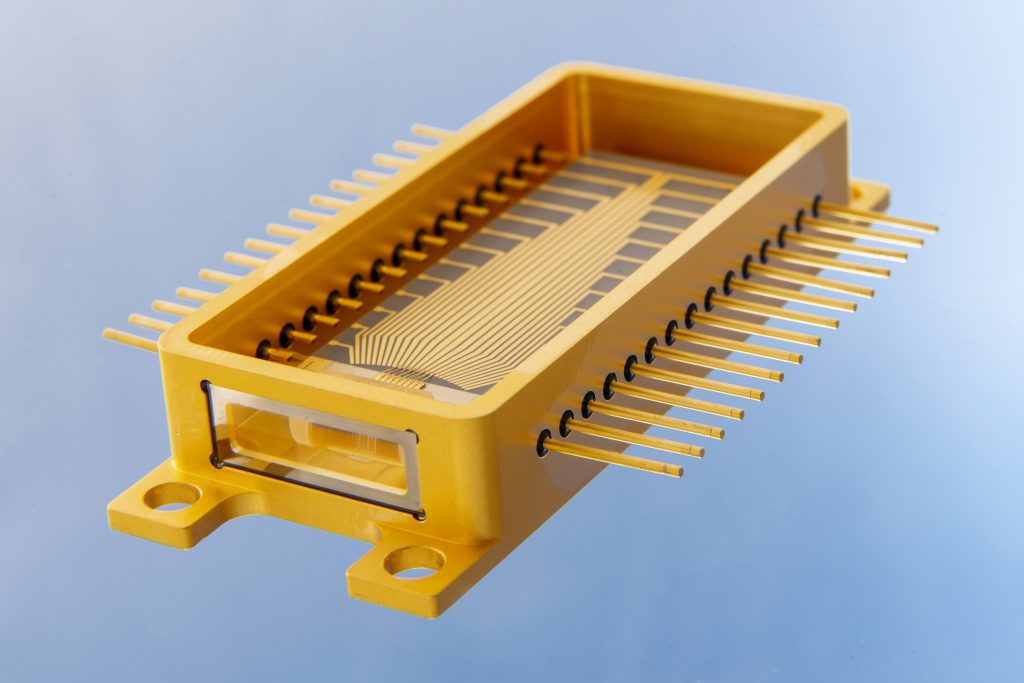

Laser Diode Packaging

ALTER UK, offers customers support in both prototype/process development for laser diode packaging as well as volume manufacturing capability.

By prototyping on the volume manufacturing tool-set Alter Technology UK, can offer a risk-free transition to manufacturing with a fully optimised and high yield process.

By prototyping on the volume manufacturing tool-set Alter Technology UK, can offer a risk-free transition to manufacturing with a fully optimised and high yield process.

A summary of Alter Technology UK, laser diode packaging expertise can be found below;

- Process Highlights

- Placement accuracies from +/- 1µm to +/-20µm

- Fully automated or manual placement

- Adjustable bond force

- 3-axis placement control

- Void free Eutectic die attach

- Control of flatness “smile”

- Epi-side down or up assembly

- Vacuum reflow processes

- Materials

- GaAs or InP

- Size

- Laser bars in excess of 10mm

- Laser single emitters to 5mm

- Package Type

- C-mount (standard sizes of 4mm to 5mm, sharp edge for accurate placement)

- CS-mount

- TO-can

- Stacks

- Eutectic solder processes including AuSn, SnAg, InAg, SnPb, BiSn (preforms, pre-deposited substrates to control solder overspill

- CuW/Cu/AlN/CuW/CVD Diamond sub-mounts and heat-sinks

Alter Technology UK, expertise and capability in Laser Diode Packaging will reduce risk and reduce time to market for your laser diode packaging requirements as well as providing a cost-effective manufacturing option.

Contact us for more information

Latest posts by Media ATN (see all)

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019