Microwave and RF testing laboratory with experts in design, packaging and testing of high reliability components. The experience and technical knowledge achieved by our engineers in the last years is major lack for most space and harsh environment companies. Our engineering services support the customers to meet the stringent quality requirements of high reliability applications.

Our PhD and engineers are responsible to ensure that all parts will meet the specific requirements of each project. A wide range of inspections are needed to guarantee that the parts are suitable for the entire mission life, which requires a deep knowledge of microwave technology design and measurement.

Our company provides in-house design, manufacture, and test of:

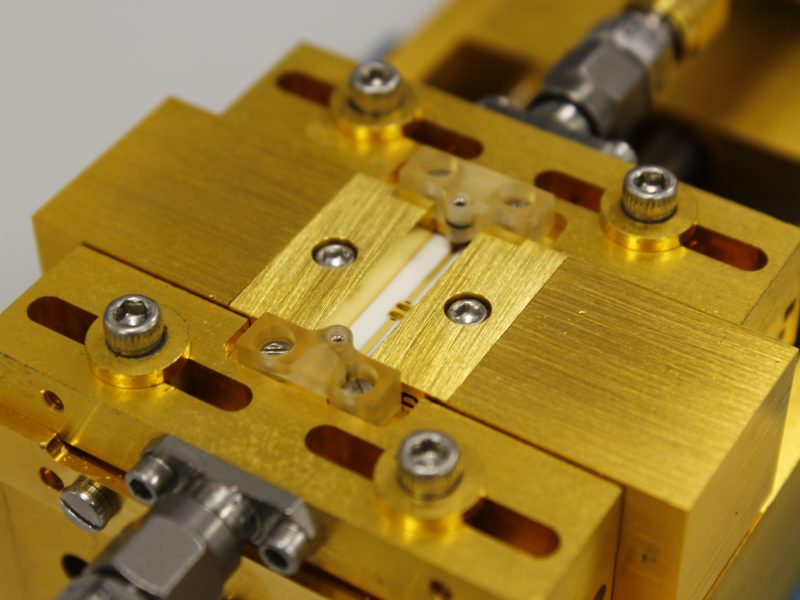

- Test fixtures for solderless measurements.

- MW PCB boards with controlled impedance routing.

- Customize calibration kits for MW devices.

- Impedance matching networks.

- Complex test setups for electrical characterization.

The know-how of our PhD and engineers is capable of supporting any microwave technology: microstrip, coaxial, rectangular waveguide

RF Testing laboratory services

Failure is not an option. We provide solutions to meet all your microwave component needs. We are in direct personal contact with our customers and suppliers and will work trustfully and performance-oriented with them together.

A meticulously scientific approach to rigorous analysis and design is performed to develop and conduct the wide range of inspections which are needed to guarantee each component performance.

With a highly trained team of testing engineers we are able to offer a wide variety of microwave lab services. From the smallest passive part to the most complex integrated components, we achieve a high level of services and outstanding testing reliability.

Main Test Services:

- Characterization of multiport MW devices.

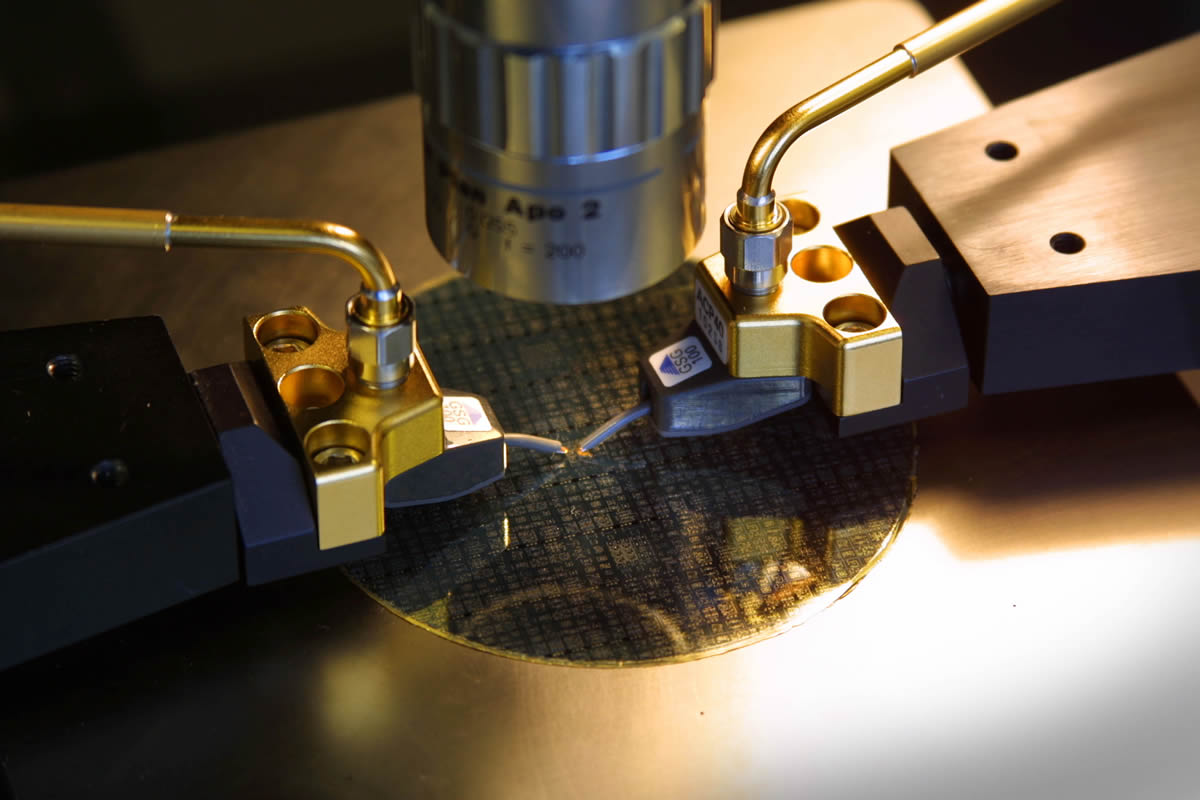

- On-wafer measurements

- Radiation Testing.

- Burn-in and life tests.

- Thermal shock.

- HAST (pressure cooking).

- Humidity test 85/85.

- Vibration testing.

Packaging & Assembly

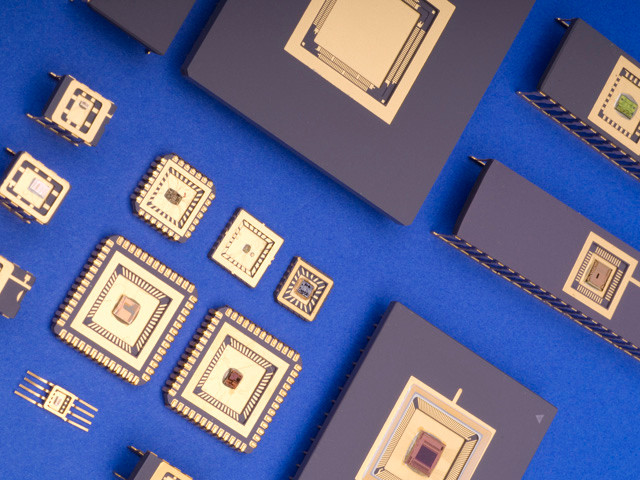

Alter Tecnology gathers all the capabilities required for the assembly and testing of MMICs.

Our expertise in packaging solutions spans the full product life-cycle: from design through prototyping, process optimization, product qualification, failure analysis, volume manufacturing and transfer to low-cost volume manufacture.

Our list of services covers a wide variety of activities:

- Die Attach: using epoxy or eutectic materials, our non-contact handling process for MMIC dies guarantees a high accuracy placement up to 10µm.

- Flip-Chip & Au Stud Bumping for bare die or wafer scale with a variety of sizes and materials and shapes.

- Wire bonding: Gold ball, Wedge-Wedge, Ribbon bonding with optimal wire bond length & loop profile.

[simple-author-box]

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019