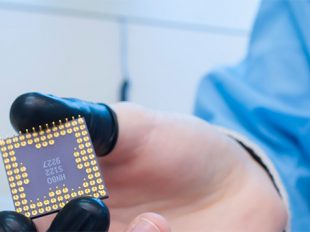

Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts and packages. One particular use of this analysis is the detection of prohibited materials, especially in the lead finish, to identify...

The purpose of this test is to verify that the markings on component parts will not become illegible when subjected to solvents (e.g. during the board cleaning process after parts assembly) or during normal handling, and that the solvents employed for the test will not cause...

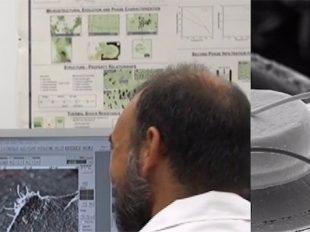

This type of inspection is performed using an electron microscope which produces images of a sample by scanning it with a focused electron beam. Interaction between the electrons and atoms in the sample generates signals that contain information about the sample’s surface...

The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices.

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The radiographic techniques reveal such flaws as presence of foreign objects, improper interconnecting wires, inhomogeneities in materials...

The purpose of vibration tests is to evaluate the effect caused on component parts by vibration in a specified frequency range. The samples are subjected to testing under different conditions, as described below, in accordance with the respective applicable standards. The test...

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) with the acquisition document. The following aspects should be considered: Marking Aspect of Materials Workmanship Sealing Leads Feedthroughs

This analytic technique may provide both qualitative and quantitative information of the composition of a surface, i.e. identification of the elements and the element weights, respectively. The technique relies on the detection and spectroscopy of secondary radiation (X-Ray)...

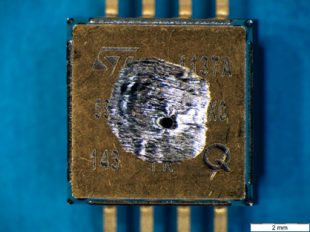

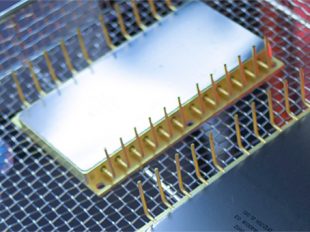

The aim of this destructive test is to demonstrate that the internal materials, design, construction and assembly of EEE parts are in accordance with the applicable acquisition document. This test can also be performed to examine unsealed devices prior to capping to verify that...

The purpose of the test is to determine the strength of the element attachment system when subjected to force in the Y1 axis, and thus to determine the integrity of materials and processes used to attach semiconductor die or surface mounted elements to package headers or other...