Radiation degrades EEE components and generates device perturbations that could lead to its malfunction or destruction. These effects are highly dependent on the radiation type: gamma radiation, heavy ions, protons, etc., but also on the device technology, the manufacturing lot...

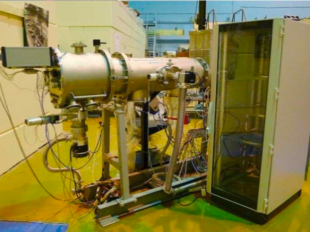

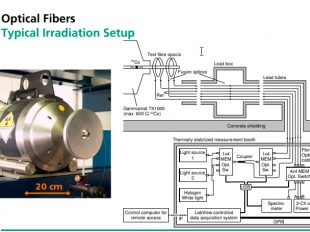

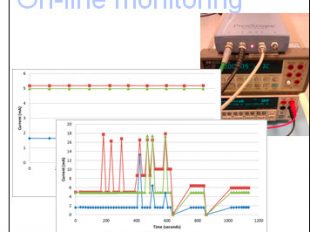

The use of radiation tools is justified as a complement of radiation test to verify and optimize the radiation hardness assurance process in the new space market and reduce some cost without a significant loss of the confidence level.

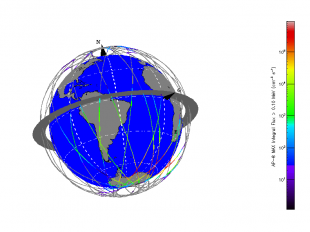

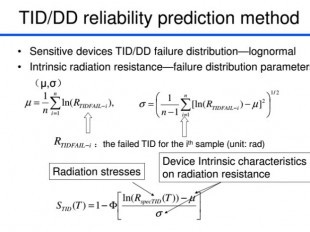

Space radiation environment is an important failure causing factor in space vehicles. Traditional reliability prediction method did not include the space radiation environment reliability. It’s the time to set up a method of space radiation environment reliability prediction.

In space applications, optocouplers may need to work at very low temperatures. Under this low temperature operating conditions, the device degradation subjected to radiation exposure may show different behaviour compared to a standard radiation test under room temperature. The...