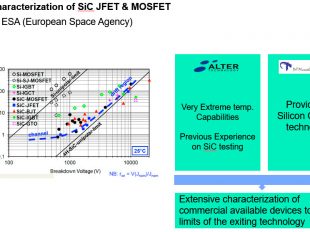

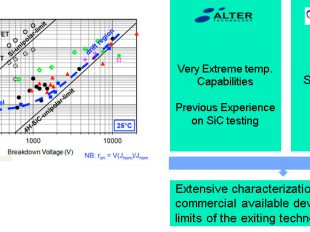

Optical & Electrical parameters; Characterization of SiC JFET & MOSFET; Prototyping and Characterisation of Radiation Hardened SIC MOS Structures; Photonic parts in Mars exploration related programmes;

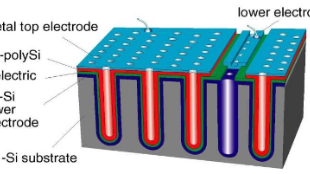

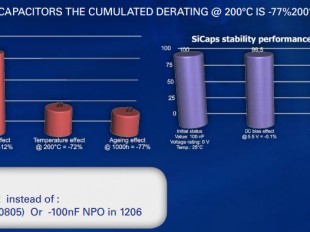

Reliability testing of passive parts for very extreme temperature applications