XRF is a non-destructive and quick analytical tool to determine the chemical elements present in the specimen. In particular, it combines low detection limit (particularly in the case of heavy elements) with quick and easy sample preparation.

- Non-destructive analysis character.

- Bulk chemical analyses of the main elements present in the specimen.

- Bulk chemical analyses of trace elements (in abundances >1 ppm) on the sample.

- Detection of Z > 11 elements.

- Recommended for materials where matrix effects are not relevant.

Practical Applications

Nowadays XRF is extensively used to test electronic systems (components, devices, PCB, and final products). These analyses are demanded for different applications such as:

- Compliance verification of RoHS regulations (Restrictions of Hazardous Substances). In this case the analysis focuses on the detection of trace amounts of heavy metals (Pb, Cd, Hg).

9th Electronics Materials & Processes for Space EMPS Workshop (Switzerland 2018).

- Prohibited Materials Analysis within the space and aerospace industry (ESCC Basic Specification 25500 -European Space Agency, ESA; and MIL-STD-1580 specification).

- Detection of counterfeit components according to the AS6171 standard issued by the SAE (Society of Aerospace Engineers).

- Positive materials identification. For instance, XRF is one of the techniques accepted by NIST (National Institute of Standards and Technology) and ASTM International (American Society for Testing and Materials) to perform acceptant-test in combination with standard reference materials (SRMs).

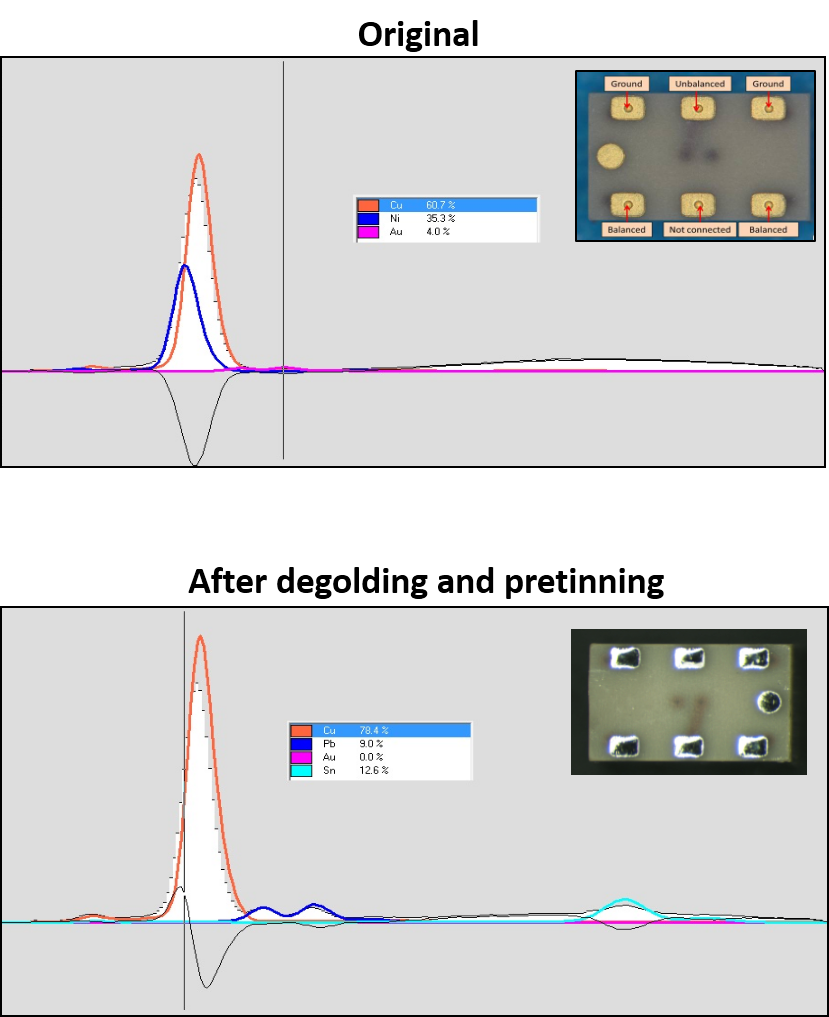

- Quality control processes; To illustrate this point the figure shows a XRF study performed at Alter Technology on of an InGaP HBT terminals before and after Degolding + Retinning. In this case technique was used to asses the quality of the of the process within a failure analysis presented by our company at the 9th Electronics Materials & Processes for Space EMPS Workshop (Switzerland 2018).

How it works

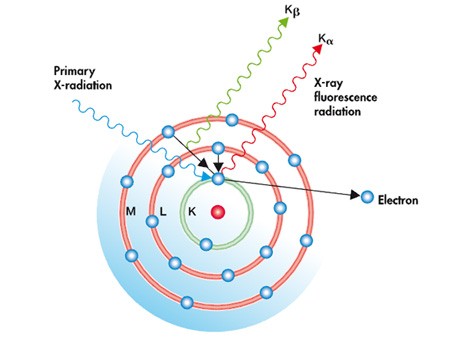

Atomic model for the X-Ray Fluorescence Analysis method.

In this process the atoms within the specimen are excited with a short-wavelength X-rays or gamma rays with a photon energy high enough to induce the ejection of tightly bound core electrons. As illustrated in the figure the generated inner vacancy is filled with an external bound-electron and the excess of energy is released (photon emission). The energy of generated X-ray photon (fluorescence) is determined by the energy of the involved electronic levels (see Kα and Kβ lines in the figure) which in turs depends on the nucleus characteristics.

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019