C-SAM is a reliable and powerful tool for the non-destructive testing of microelectronic parts and base materials. Moreover it is mandatory for different applications such as those described below for different sectors.

mandatory for different applications such as those described below for different sectors.

In order to provide a fast reply to our customer needs our Virtual Lab platform for Remote Testing grants immediate access to our test results and fast communication with our engineers during and after the test.

Space

Scanning acoustic microscopy (SAM) is essential in the non-destructive screening of potential defects in critical systems. Therefore, space agencies routinely use and require SAM inspection as a mandatory test before the implementation in spacecraft, for instance in the regulations included below. This is so due to the capability to perform detailed and comprehensive internal inspections in complex 3D assemblies.

- ESCC 25200 “Application of Scanning Acoustic Microscopy to Plastic Encapsulated Devices”

- IPC JEDEC J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices

- NASA PEM-INST-001 “Instructions for Plastic Encapsulated Microcircuit (PEM) Selection, Screening, and Qualification” (NASA/TP—2003–2122)

- NASA EEE-INST-002 “Instruction for EEE Parts Selection Screening Qualification and Derating” (NASA TP-2003-212242)

Defense and Aerospace

Military, aerospace and space applications define the higher quality levels in terms of reliability and durability, even under aggressive environmental working conditions. According to these specifications EEE parts must be systematically analyzed after stress tests by either destructive and non-destructive internal inspections. Hence, C-SAM analyses are conducted within these tests as part of the non destructive verification of microelectronic components.

- MIL-STD-883 Test Method 2030 “Ultrasonic Inspection of die attach”

- MIL-STD-1580 “Destructive Physical Analysis for Electronic Electromagnetic and Electromechanical Parts”

- MIL-PRF-123 ”Capacitors Fixed Ceramic Dielectric (Temperature Stable and General Purpose), High Reliability, General Specification For”

- MIL-PRF-31033 “Capacitor Fixed Ceramic Dielectric High Reliability Discoidal General Specification For”

- MIL-PRF-49470 Capacitors, Fixed Ceramic Dielectric Switch Mode Power Supply (General Purpose and Temperature Stable) Standard Reliability and High Reliability, General Specification For

Automotive

Acoustic microscopy is commonly used in the inspection of materials and composites, including those present in the automotive industry.  In addition, microelectronics parts are extending their applications within motor vehicles, where they are providing new functionalities and adding value. Some examples are the implementation of cameras, proximity sensors, engine controls and other systems that have to be able to withstand outdoor environmental conditions. With this concerns, non-destructive quality control of EEE parts and materials by acoustic microscopy assures the suitable performance for such applications.

In addition, microelectronics parts are extending their applications within motor vehicles, where they are providing new functionalities and adding value. Some examples are the implementation of cameras, proximity sensors, engine controls and other systems that have to be able to withstand outdoor environmental conditions. With this concerns, non-destructive quality control of EEE parts and materials by acoustic microscopy assures the suitable performance for such applications.

- Control devices

- Sensors

- Power electronics

- Sealing systems

- Welded connections

- Soldered systems

- Sintered layers

- Compound materials

Power and energy

Power and energy applications impose high working temperatures. In such devices a suitable thermal management is critical for the system performance. Being the high sensitivity to adhesion issues one the main advantages of SAM, the technique is particularly suitable for the detailed inspection of thermal interfaces of EEE parts conceived for these applications.

- IGBT modules

- Heat sinks

- Thin film multilayer systems (sintered and soldered layers)

- Semiconductor (diodes, transistors, photovoltaics junctions)

- Metallization

Material analysis

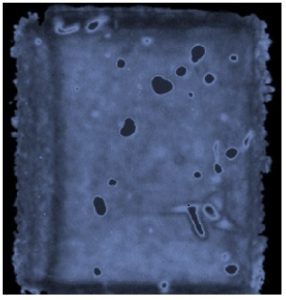

Detection of porosity in a ceramic chip capacitors

In addition to assembly issues, scanning acoustic microscopy is also an advantageous non-destructive analysis technique for the characterization of bulk materials. In fact it is particularly effective for the detection of micrometric air defects (voids in the figure) even within low density materials (plastics and mold compounds) or for the inspection of x-ray opaque system (e.g. metals). The image shows the detection of voids within a ceramic capacitor.

- Ceramic and sintered materials.

- Composites and hybrid materials

- Si ingots and wafers

- Bonded and molded plastics

- Hard metals

Contact our team

- Scanning Acoustic Microscopy on Ceramic Capacitors - 18th May 2020

- Non-destructive detection of micrometric internal features within EEE microelectronic systems. - 3rd September 2019

- Acoustic Inspection of Hybrid Systems on Laminated Substrates - 3rd September 2019