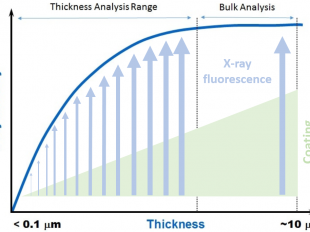

The thickness of metallic coatings is routinely determined by X-ray fluorescence spectrometry. This provides a basis for assessing the quality of coated materials and therefore influences decisions regarding disposition (acceptability) of coated product as well as control of... Continue reading

The purpose of this test is to measure bond strengths, to evaluate bond strength distributions and to determine compliance with specified bond strength requirements of the applicable acquisition document in order to ensure the proper manufacturing process and long-term... Continue reading

Burn-in test is an electrical stress test that employs voltage and temperature to accelerate the electrical failure of a device. Continue reading

Destructive Physical Analysis, dpa , is a systematic, logical, detailed examination of EEE parts during various stages of physical disassembly. This activity is performed to verify that the manufacturing lot quality and construction are in accordance with the detailed... Continue reading