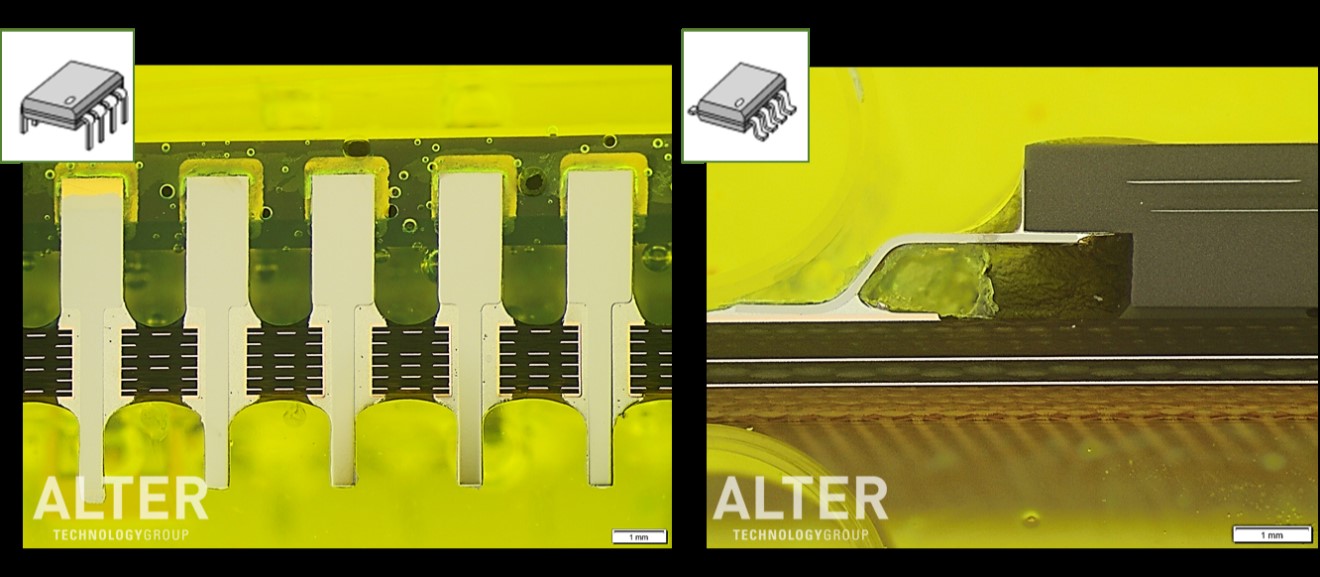

Cross-sectioned devices were metallographic prepared in ALTER TECHNOLOGY Materials & Processes Laboratory, recognized as a recommended facility for such activity by ESA authority (MEMO ESA-TECMSP-MO-013165).

Cross-sectioned devices were metallographic prepared in ALTER TECHNOLOGY Materials & Processes Laboratory, recognized as a recommended facility for such activity by ESA authority (MEMO ESA-TECMSP-MO-013165).

Sample & Method

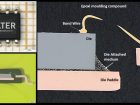

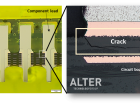

Devices assembled to a PCB have been submitted to the ECSS verification program. Metallographic analysis allows us to check the status of such devices and their solder connections after performing different stress tests (Vibration & Thermal Cycling).

Remark

Assembly process of THT or SMT onto PCBs for spacecraft applications follow well-established design requirements based on specifications prepared by ECSS (ECSS-Q-ST-70-08C & ECSS-Q-ST-70-38C), NASA and IPC (IPC-6012). These documents collect not only the technical requirements but also the quality assurance provisions for the manufacture and verification of such high-reliability electronic circuits.

These standards also define the verification testing, which includes accelerating reliability testing, in order to assess the solder failure mechanisms and to calculate the effective life of such devices, and the accept/reject criteria for the final inspection.

Contact us for more information

- MacroVoids in assembled BGA packages - 14th August 2019

- Microsection Inspection / Constructional Analysis - 23rd July 2019

- Microsection Inspection / Failure Analysis - 19th July 2019