-New space missions impose stricter requirements on storage, vacuum conditions and operating temperature, exceeding the standard -55ºC / +125ºC range

-Parts reliability has to be reanalysed to ensure mission performance

-Specific characterization delta qualification tests have to be performed at equipment level as per mission requirements

Specific capabilities for extreme temperature characterization (I)

Very extreme temperature testing

Alter Technology has developed specific capabilities to support very extreme temperature testing on the full range of parts, equipments and materials

- Several cryogenic chambers with temperature range -185ºC to +315ºC

- Open-air thermal tables with humidity control

- Customized thermal profile and temperature increase rate up to +48ºC/min

- Specific feedthrough for the electrical, optical and mechanical parameters read & record and continuous monitoring

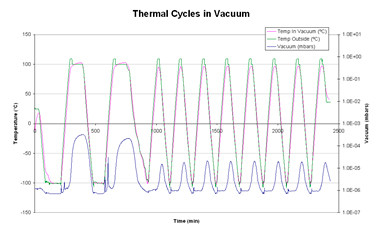

- Thermal vacuum up to 2·10-7mbars

- Combined radiation environment test (TD and SEE)

- Custom setup for combined testing (radiation + temperature + vacuum + mechanical stress + …)

Specific capabilities for extreme temperature characterization (II)

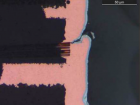

Cryogenic chambers available:

200 x 200 x 250 mm (4 chambers)

300 x 300 x 400 mm (1 chamber)

Thermal profile shape: as per customer requirements

Temperature range: -184ºC (limited by LN2) to + 200ºC (limited by vacuum rings)

Achievable Vacuum level:

- Fully customized up to <2·10-6mbars

Temperature increase rate:

- Controllable up to approx. 2ºC/min

Valves for breaking vacuum with clean gas (normally nitrogen)

Available vacuum feedthroughs:

- Electrical (DB25 and DB9 connectors)

- Optical feedthrough for fibers

- Multimode (400nm to 2100nm)

- Monomode (1550nm, 850nm…)

- RF-feedthrough (upon request)

- Thermocouples

- Windows for non-fiber lasers

Characterization of EEE parts

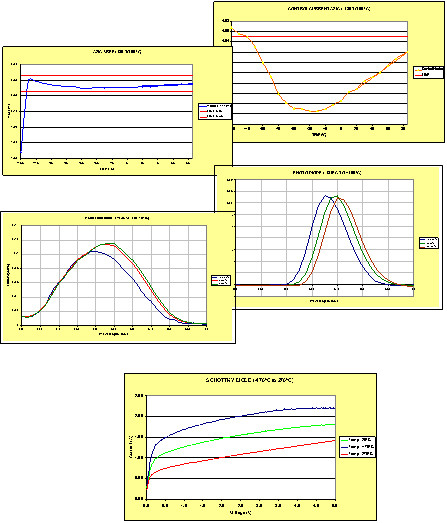

- Alter Technology has performed several R&D projects concerning characterization of EEE parts and subsystems at very extreme temperatures (-190ºC to 300ºC)

- We have capabilities to perform characterization of all optical and electrical parameters of various electronic component families (electro-optical, ASIC, RF, Discrete) in order to assess their functioning in such conditions

- ASIC CQFP100 (-135 TO 90ºC)

- BiCMOS TECHNOLOGY

- ANALOG ACQUSITION & A/D CONV.

Development of technologies for space applications (Very extreme temperatures)

Development of silicon carbide technologies:

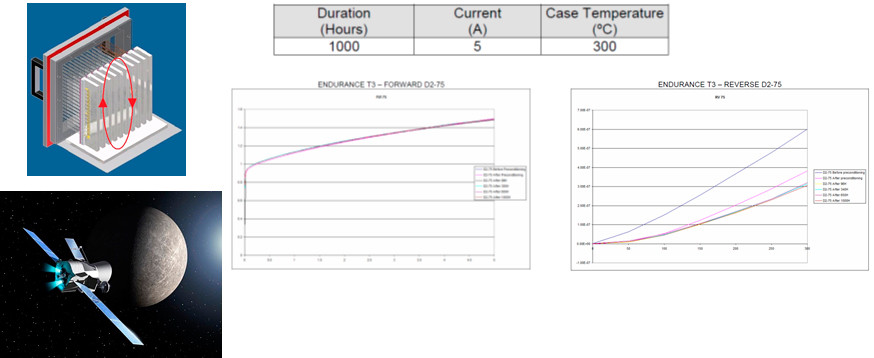

- Specific agreement with D+T (CSIC) Spanish R&D centre for the development of SiC technologies for space applications

- Evaluation, screening and qualification of SiC blocking diodes for Bepi Colombo and Solar Orbiter

- SiC-JFET characterization and evaluation

- Full characterization of high-voltage SiC diodes

Evaluation and qualification of SiC schottky diodes for Bepi Colombo

See an example on our website: Characterization of SiC JFET & MOSFET

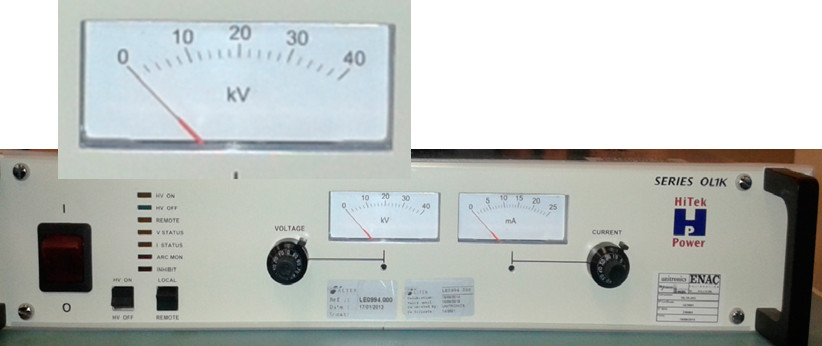

High voltage resources

- Keithley SMU High Voltage Supply 2657A (3000V, 20 mA)

Diode characterization

- Hitek Power OL1K (40kV, 25mA)

See an example on our website: Project: Developing of 1200V SiC Diode

- Quantum Key Distribution - 7th November 2022

- Conducted Immunity - 20th May 2019

- Electrical transients Test - 2nd May 2019