Internal Visual Inspection

The aim of this destructive test is to demonstrate that the internal materials, design, construction and assembly of EEE parts are in accordance with the applicable acquisition document. This test can also be performed to examine unsealed devices prior to capping to verify that no damage and/or defects have appeared as a result of prior testing (see Pre-cap Inspection).

It is intended principally as a screening test to detect processing and assembly faults in components, as well as to allow the removal of defective components prior to capping. The magnification to be used, the area to be inspected, and the faults to be looked for can vary significantly from one component type to another, however the appropriate specifications, test methods and standards added to the experience of the inspector carrying out the test serve as guidance during the inspection.

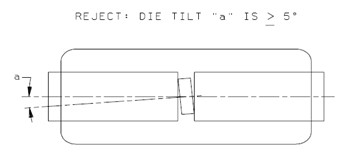

FIGURE: MIL-STD-750E, Test Method 2074 D.1.3 Alignment

FIGURE: Hard glass diode showing tilted die/plugs

To perform this test, the devices are opened using techniques that do not damage or contaminate their internal structure (see Decapsulation Analysis). A wide range of optical instruments is available for performing optical inspections using bright-field and dark-field illumination, differential interference contrast, etc.

- External Visual Inspection Electronic Components | EEE Parts - 9th December 2015

- Internal Visual Inspection Electronic Components | EEE Parts - 9th December 2015

- Penetrant Dye Gross Leak Electronic Components | EEE Parts - 9th December 2015