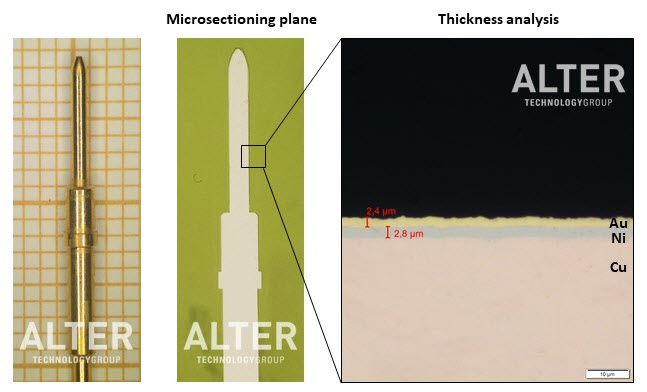

Cross-sectioned pins were metallographic prepared in ALTER TECHNOLOGY Materials & Processes Laboratory, recognized as a recommended facility for such activity by ESA authority (MEMO ESA-TECMSP-MO-013165).

Sample & Method

Metallographic analysis of pins allows us to check both the uniformity and thickness of plating and underplating coatings of pins. The major challenge of the sectioning process is to avoid smearing of the coatings. I order to obtain a high-quality surface the polishing parameters have to be adjusted depending on the coating material. Thickness measurements are collected using a metallographic microscope equipped with quantitative imaging software. Scanning Electron Microscopy is used to measure coating thickness down to microns.

Remark

This quantitative analysis allows us to evaluate if coatings applied to pins are within constructional requirements or standard specifications.

Contact us for more information

- MacroVoids in assembled BGA packages - 14th August 2019

- Microsection Inspection / Constructional Analysis - 23rd July 2019

- Microsection Inspection / Failure Analysis - 19th July 2019