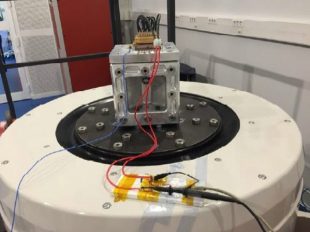

As it has been mentioned in “Vibration Test on Hi-Rel for EEE Parts”, vibration tests are important to check the reliability of the components/assemblies. These tests can be a headache and suppose a great cost if the design of the device and the fixing tool are not properly done... Continue reading

Vibration Tests on HI-ReL EEE Parts: Types of test and test flow for space applications. Depending of the intended application electrical components are exposed to either transitory or permanent dynamic mechanical stress which can impair the performance (e.g. mechanically... Continue reading

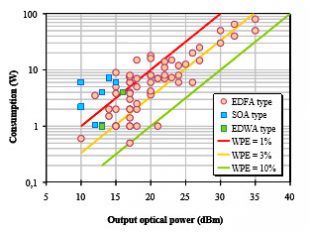

This paper describes the activities and results of an ESA-funded project concerned with the assessment of optical amplifier technologies and products for applications in fiber optic subsystems of future satellite payloads. On-board applications are briefly introduced, together... Continue reading

PIND ( Particle Impact Noise Detection Test ) testing is performed in order to detect the presence of loose particles inside a device cavity. Loose particle contamination is often caused by dirt, fibers, solder residues and other elements trapped inside the cavity during the... Continue reading

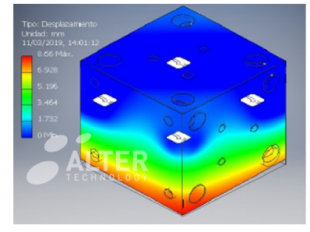

The purpose of vibration tests is to evaluate the effect caused on component parts by vibration in a specified frequency range. The samples are subjected to testing under different conditions, as described below, in accordance with the respective applicable standards. The test... Continue reading

Performing an environmental test means subjecting the device or system to certain environmental conditions (cold, dry heat, relative humidity, etc.) in order to check if the operational parameters remain within the range defined by the applicable regulations. Sometimes it is... Continue reading

In the railway industry, safety of electronics systems is a priority requirement. They must be tested to comply with the industry standards for hardware and software. These include, among others, rolling stock equipment as well as fixed installation and signaling equipment. Continue reading