LOT ACCEPTANCE TEST / QCI (sampling basis)

To provide greater reliability assurance with respect to environmental, mechanical assembly and endurance of the devices.

Within the ESA/SCC (now ESCC) system the Lot Acceptance Tests (now Lot Validation tests) are specified in Chart V (now Chart F3) of the appropriate Generic Specification and indicate which tests are performed, how many parts are required for each test and how many failures are permitted for each of the tests.

Within MIL system, QCI/TCI are specified in the generic specification:

• QCI group A and B correspond to Electrical test and LAT3 tests

• QCI group C corresponds to Endurance subgroup (LAT2 and part of LAT1)

• QCI group D corresponds to Mechanical subgroup (LAT1)

• QCI group E corresponds to Radiation tests

SERVICES & CAPABILITIES

Show All

(23)

receiving inspection (1)

Incoming Inspection (7)

Destructive Physical Analysis (21)

Sort By None

Sort By Date

Sort By Title

Sort By Author

Vibration Tests Electronic Parts

María Teresa Rodríguez

The purpose of vibration tests is to evaluate the effect caused on component parts by vibration in a specified frequency range. The samples...

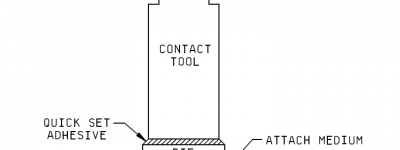

Substrate Attach Strength – Die Shear Strength | EEE Parts

José Cándido Vázquez Cárdeno

The purpose of the test is to determine the strength of the element attachment system when subjected to force in the Y1 axis, and thus to de...

SEM EDS, Internal Material Analysis | EEE Parts

Francisco Javier Aparicio Rebollo

This analytic technique may provide both qualitative and quantitative information of the composition of a surface, i.e. identification of th...

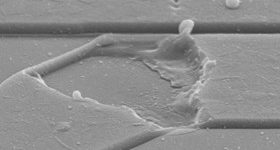

Scanning Electron Microscope SEM – FIB Inspections Focused Ion Beam | Hi Rel Parts

Francisco Javier Aparicio Rebollo

This type of inspection is performed using an electron microscope which produces images of a sample by scanning it with a focused electron b...

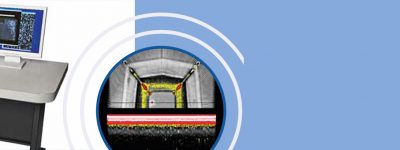

Scanning Acoustic Microscopy CSAM | EEE Parts

Media ATN

Scanning Acoustic Microscopy (SAM) is an inspection that uses focused sound to investigate, measure, or obtain an internal image of an objec...

Resistance to Solvent or Marking Permanence Test | EEE Parts

Jesús Enrique Barbero Muñoz

The purpose of this test is to verify that the markings on component parts will not become illegible when subjected to solvents (e.g. during...

Residual Gas Analysis – HI Rel Electronics Parts

Dimas Morilla

Residual Gas Analysis, also known as Internal Gas Analysis (IGA), is a destructive test which is performed to examine the atmosphere inside...

Receiving Inspection | EEE Parts

Media ATN

Receiving Inspection is an acceptance activity aimed at confirming that the components received are in accordance with the requirements of t...

Radiographic Inspection 3D X Ray – 2D | Hi Rel Electronics Parts

José Cándido Vázquez Cárdeno

The purpose of radiographic inspection is to detect internal physical defects which are not otherwise visible in electronic components. The...

PIND test – Particle Impact Noise Detection | EEE Parts

Adrián Cembrano Pérez

PIND ( Particle Impact Noise Detection Test ) testing is performed in order to detect the presence of loose particles inside a device cavit...

Penetrant Dye Gross Leak Electronic Components | EEE Parts

David Ramirez - Cruzado

Penetrant dye gross leak test is used to identify leakage pathways within hermetic and non-hermetic devices, such as glass body devices or p...

Material Analysis EEE Electronic Components

Francisco Javier Aparicio Rebollo

Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts an...

Lead Integrity Test Electronic Components | EEE Parts

Jesús Enrique Barbero Muñoz

Lead integrity test is performed to determine the integrity of the device leads (terminals), welds and seals. During the execution of this t...

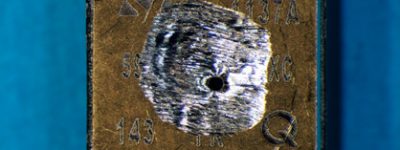

Internal Visual Inspection Electronic Components | EEE Parts

David Ramirez - Cruzado

The aim of this destructive test is to demonstrate that the internal materials, design, construction and assembly of EEE parts are in accord...

Incoming Inspection Electronic Components | EEE Parts

Antonio José Rey

The purpose of the incoming inspection is to identify potentially non-conforming parts, prior to placing the material in the inventory or mo...

Glassivation Integrity Electronic Components | EEE Parts

Francisco Javier Aparicio Rebollo

This test is performed to verify the structural quality of the glassivation layer in aluminium metallized semiconductor devices or microcirc...

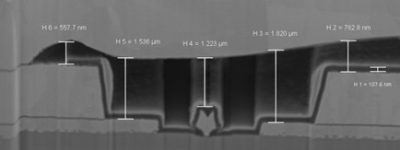

Focused Ion Beam (FIB) Micro-Sectioning | HI Rel Parts

Francisco Javier Aparicio Rebollo

Focused ion beam, also known as ion milling, is a technique used particularly in the semiconductor industry and materials science for site-s...

External Visual Inspection Electronic Components | EEE Parts

David Ramirez - Cruzado

The aim of this process is to verify the conformity of the exterior of electrical, electronic and electromechanical components (EEE parts) w...

Dimensions and Weight Check | EEE Parts

Media ATN

The purpose of the inspection is to detect: Manufacturer deviations Handling damages that could affect the device assembly and its final...

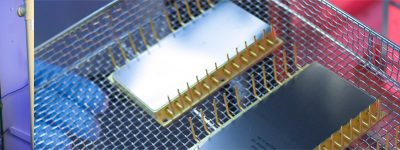

Destructive Physical Analysis DPA | EEE Parts

Lope Rescalvo

Destructive Physical Analysis, dpa , is a systematic, logical, detailed examination of EEE parts during various stages of physical disassemb...

Decapsulation testing services Electronic Components | EEE Parts

Francisco Javier Aparicio Rebollo

Decapsulation of packaged devices exposes the internal elements of the device under test. Opening devices by this method allows the inspecti...

Load More